Mastering Roof Inspections: Asphalt Composition Shingles, Part 25

by Kenton Shepard and Nick Gromicko, CMI®

The purpose of the series “Mastering Roof Inspections” is to teach home inspectors, as well as insurance and roofing professionals, how to recognize proper and improper conditions while inspecting steep-slope, residential roofs. This series covers roof framing, roofing materials, the attic, and the conditions that affect the roofing materials and components, including wind and hail.

One of the key components in the wind resistance of shingles is the fasteners that hold them to the roof.

How effectively fasteners hold shingles in place depends on four things:

- the type of fastener;

- proper fastener installation;

- fastener placement; and

- the holding power of the substrate.

Disclaim Proper Fastening

You should disclaim proper fastening of asphalt shingles in your report and in your inspection agreement. Confirming proper fastening would require breaking the bonds of all the adhesive strips to examine all the fasteners, and you will not do that. For asphalt shingles, the adhesive strip is the most important component in resisting wind damage.

Your disclaimer should state that you don’t inspect each fastener, and tell why.

If you do break the bonds of a few adhesive strips to check a representative number of areas, your report should state that you inspected a representative number of fasteners only.

If you don’t inspect fasteners and fail to mention this in your report, you may be found liable in court for roof failure related to proper fastening. Disclaim confirmation of proper fastening.

Jurisdictional Requirements

Another reason not to confirm proper fastener installation is that you’d need to be sure of the jurisdiction in which the property you’re inspecting is located, and you’d need to be sure of the jurisdictional requirements. If you’re wrong about either one, you could find yourself being sued for a new roof.

Fastener Type

The type of fastener used to fasten the shingles is especially important in resisting wind uplift and pull-through. Fasteners for asphalt shingles should be roofing nails or staples. The head of a roofing nail or the crown of a staple is what actually holds a shingle in place.

Although both nails and staples have been used in the past, staples are often not recommended in areas subject to high winds, and they are not allowed in new construction by the IRC.

Shingles fastened with staples are often not warranted against wind blow-off.

Both nails and staples have sufficient strength to resist small uplift load on the shingles, as long as the tabs remain sealed. If staples are properly installed, they offer nearly the same wind resistance as nails.

The problem with staples is the orientation of the staple crown.

To hold properly, staples need to be installed with the crowns aligned with the long axis of the shingle. As an installer uses an air-powered staple gun, his natural tendency is to rotate his body.

Unless he also rotates his wrist at the same time, the orientation of the staple crowns will reflect this rotation.

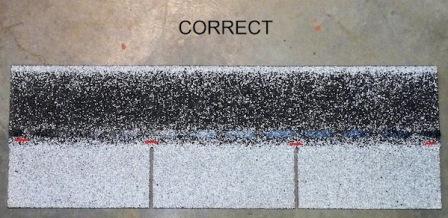

This roof has staples that were poorly installed, and the shingles were poorly bonded, so their wind resistance was low.

The minimum staple crown width is 15/16-inch. Properly installed, stapled shingles will usually withstand wind speeds of up to 60 miles per hour. Upgrading the fastening system requires re-fastening the shingles with roofing nails. The shingles may need to be hand-sealed afterward, since the adhesive bond may not re-seal adequately.

If you see staples used to fasten asphalt shingles on a home that is in an area that can experience high winds, you should mention in your report that staples are not the preferred method of fastening. If they are not allowed in new construction in the area where the home was built, mention that fact, too. Don’t call their use a defect unless you know it’s a defect. If staples were allowed at the time the shingles were installed, it’s not a defective installation.

Re-fastening can be difficult or impossible. The adhesive strips have to be broken on all the affected shingles, the shingles have to be re-fastened, and then all the shingles have to be hand-sealed. Shingles may be irreparably damaged, or they may never bond completely. Do not recommend that shingles be re-fastened. Just describe the condition, and leave it at that.

Nails

Some shingle manufacturers specify that their shingles be fastened with nails. You won’t know which shingles those are, so that’s one more reason that confirming proper fastening exceeds the scope of your inspection.

Nails should be corrosion-resistant. Corrosion-resistant nails include galvanized, copper, aluminum and stainless steel.

**************************************************

Learn how to master a roof inspection from beginning to end by reading the entire InterNACHI series: Mastering Roof Inspections.

Take InterNACHI’s free, online Roofing Inspection Course

Mastering Roof Inspections

Roofing Underlayment Types

Inspecting Underlayment on Roofs

Fall-Arrest Systems

Roofing (consumer-targeted)

More inspection articles like this