Inspecting the Kitchen Exhaust

by Nick Gromicko, CMI® and Ben Gromicko

Home inspectors should know how to inspect the kitchen exhaust system. Regardless of what kind of ventilation system is installed for the rest of the house, an exhaust fan should be installed in the kitchen to exhaust moisture and odors associated with cooking. The exhaust fan is typically mounted in a range hood or cabinet or on the wall over the kitchen stove. A local intermittent exhaust fan in the kitchen should reduce the levels of contaminants and moisture in the kitchen. The minimum best practice for a local intermittent exhaust fan in the kitchen is to have the fan ducted to exhaust outside of the home, not into the attic.

exhaust system. Regardless of what kind of ventilation system is installed for the rest of the house, an exhaust fan should be installed in the kitchen to exhaust moisture and odors associated with cooking. The exhaust fan is typically mounted in a range hood or cabinet or on the wall over the kitchen stove. A local intermittent exhaust fan in the kitchen should reduce the levels of contaminants and moisture in the kitchen. The minimum best practice for a local intermittent exhaust fan in the kitchen is to have the fan ducted to exhaust outside of the home, not into the attic.

Recirculating fans that draw air through a filter and discharge it back into the room are not acceptable. Operable windows are a nice feature but they should not be relied on for consistent ventilation.

ENERGY STAR-rated exhaust fans should be selected that have low sone ratings, low power draw and, in some cases, multiple speeds for spot exhaust and continuous ventilation.

Although a single-point exhaust fan, such as a kitchen fan, could be used to provide code-required whole-house ventilation, this strategy is not recommended.

Kitchen exhaust fans may be installed by an HVAC contractor or by a kitchen range installer, if it is part of that system.

Air Flow Requirements

To fulfill the local exhaust air flow requirements of modern construction standards, kitchen fans can be run intermittently (occupant-controlled) or continuously. Kitchen fans operated intermittently should have a flow rate of 100 cfm or more, and continuous fans should have a flow rate of 25 cfm. If the fan is set to run continuously and the flow rate is less than 400 cfm, the sound rating should be no more than 3 sones. Exhaust fans operating in excess of 400 cfm must be provided with makeup air systems that will automatically start and operate simultaneously with the exhaust system and provide makeup air at a rate equivalent to the exhaust.

Ductless Range Hoods

Listed and labeled ductless range hoods may be allowed to recirculate, but only where they are installed in accordance with the manufacturer’s installation instructions, and where mechanical or natural ventilation is otherwise provided according to the air flow requirements.

Size

For a continuous rate of ≥ 5 ACH (air exchanges per hour), ENERGY STAR recommends a fan that provides more than 5 ACH in order to pull the required amount of air. For an intermittent rate of ≥ 100 cfm, ENERGY STAR recommends a fan with a rating of 150 to 200 cfm. ENERGY STAR-rated fans are energy-efficient and have low noise levels.

Fan Location

The fan should be installed in the range hood, the cabinet above the stove, or on the wall above the stove. The manufacturer’s instructions should be followed during installation. The fan may be integrated into a microwave oven mounted into a cabinet above the stove. There may be an opening in the ceiling for the fan or exhaust duct. It should be no wider than needed to fit the fan or duct. Air sealing, such as caulk or spray foam, should be observed at the opening. The exhaust duct should be connected to the fan box with mechanical fasteners, metal tape, and/or mastic, and not regular cloth-backed duct tape.

Venting

The kitchen vent fan must exhaust directly to the outside, not into an attic, crawlspace, or a space between floors. The duct should be smooth and straight, with as few bends as possible. The fan’s installation instructions should specify the diameter of the duct; small-diameter ducts could trap grease, creating a fire hazard. The duct should be made of metal and any seams should be fastened and sealed, preferably with mastic. It should be routed so that it is out of the way of other ducts and equipment in the attic, and care should be taken so that it's not dented or crushed during or after installation.

This from the 2009 IRC:

SECTION M1503

RANGE HOODS

M1503.1 General. Range hoods shall discharge to the outdoors through a single-wall duct. The duct serving the hood shall have a smooth interior surface, shall be air tight and shall be equipped with a backdraft damper. Ducts serving range hoods shall not terminate in an attic or crawl space or areas inside the building.Exception: Where installed in accordance with manufacturer's installation instructions, and where mechanical or natural ventilation is otherwise provided, listed and labeled ductless range hoods shall not be required to discharge to the outdoors.

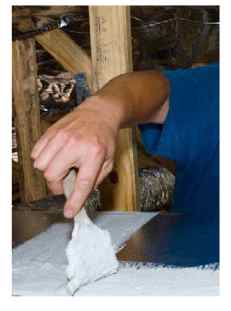

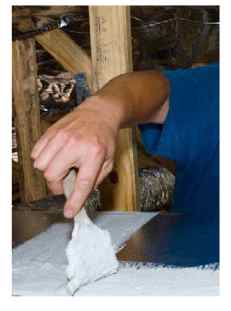

Mastic

All kitchen exhaust ducts should be air tight, fastened and sealed. Ducts should be sealed with duct mastic and/or metal tape that meets the requirements of the Underwriters Laboratory UL-181, UL-181A or 181B, or with aerosol sealant systems that meet the requirements of UL 723 (CEC 2005). Regular cloth-backed duct tape should not be used because it can dry out and fail quickly. Duct systems should not use cloth-back, rubber-adhesive duct tape regardless of UL designation, unless it is installed in combination with mastic and clamps.

Above: Mastic (a thick, gooey substance) is being applied on to the duct seams and joints. (Photo source: Habitat for Humanity, Lakeland, FL)

Mastic is a thick, gooey, non-hardening substance that is spread onto the duct seams with a paintbrush or a putty knife. For additional strength with seams that are wider than 1/8 inch, the gap should be covered with fiberglass mesh tape then mastic applied. For further reference, see Section 4.4.1 of the California Energy Commission. 2005. 2005 Building Energy Efficiency Standards: Residential Compliance Manual. CEC-400-2005-005-CMF. Sacramento, CA.

Duct Material

With few exceptions, single-wall ducts serving range hoods shall be constructed of galvanized steel, copper or stainless steel.

Exterior Vent Location

The exhaust duct outlet vent on the exterior of the home should be located at least 10 feet from any air inlet. The outside termination should be covered with louvers, a screen, or a grille. The exhaust air should not be directed onto a walkway. The range hood duct should have a smooth interior finish, be airtight, and equipped with a backdraft damper (2009 IRC M1503). If the fan is integrated with a microwave oven installed over the stove, it should be installed according to the manufacturer’s instructions and 2009 IRC Section M1504. Exhaust hoods installed over domestic open-top broiler units should be installed with a minimum clearance above the cooktop of 24 inches, and the hood should extend the full width and depth of the cooktop and follow other requirements of 2009 IRC M1505.

Inspection

Visually inspect the fan and duct installation and observe the fan for functional operation and air flow.

Also:

- Check that the fan exhausts outside, not into the attic.

- Check that it is set to exhaust, not recirculate.

- Check that any dampers on the outside termination are able to open freely.

- Check that any openings that are cut into the ceiling for the fan or exhaust duct are air sealed, and that the exhaust duct is sealed to the fan with both mechanical fasteners and mastic for a flex duct or caulk or spray foam for a rigid duct.

Fan exhausts outside: good.

Exhaust duct is not sealed: bad.

Exhaust duct is sealed with mastic: good.

CFM is inadequate: bad.

Duct not mechanically fastened: bad.

Insulated duct sealed with mastic: good.

Duct opening sealed with mastic and mesh: good.