STANDARDS OF PRACTICE

The International Standards of Practice for inspecting the roof system is located at www.nachi.org/sop.

MASTERING ROOF INSPECTIONS

To learn about inspecting asphalt shingle roofs, please visit Mastering Roof Inspections.

DESIGNED TO SHED

Asphalt shingles are designed to be layered. And the layering is designed to shed water. An asphalt shingle roof is designed to be water-resistant -- not waterproof. A shingle roof essentially relies on the slope of the roof to shed the water.

REINFORCED

Asphalt shingles are reinforced. They are referred to either "organic-reinforced asphalt shingles" or "glass-fiber-reinforced asphalt shingles." Most of the shingles in the North America are "glass-fiber reinforced."

The shingles installed are laminated lifetime shingles. More information from the manufacturer here.

Observation

There is a missing fastener on the bottom course where the shingles but together.

STANDARD NAILING PATTERN - five nails per shingle

ENHANCED NAILING PATTERN - six nails per shingle* required by some local codes and required for enhanced wind coverage on certain products.

Observation

There is a shingle damaged or torn. The material may not perform as intended and may deteriorate quicker.

Observation

The rubber gasket on the plumbing vent is dimpled inward and will collect water, they are meant to be higher on the vent to shed water. Many have a tab so that it can be pulled into place.

Observation

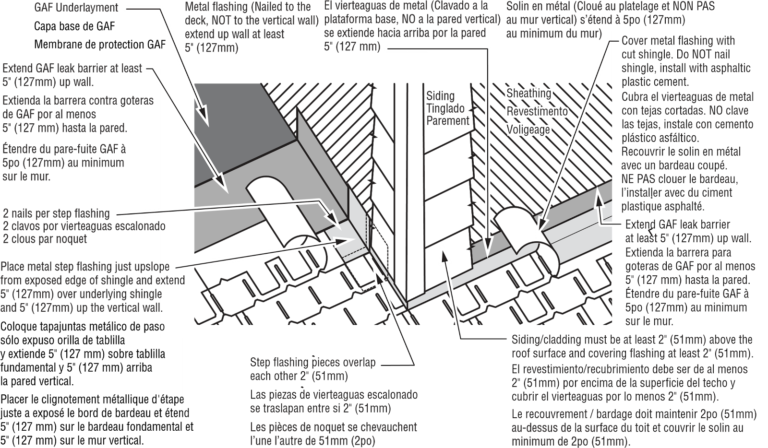

The step flashing is not secured. 2 nails per step flashing is what the manufacturer recommends. Metal flashing (Nailed to the deck, NOT to the vertical wall) extend up wall at least 5" (127mm). Step flashing pieces should overlap each other 2".

Observation

Extend leak barrier at least 5" (127mm) up wall.

Offset Pattern

The asphalt shingles should be installed with an offset pattern according to the shingle manufacturer's installation recommendations.

It is a common installation procedure to create an offset pattern for the installation of asphalt shingles.

STARTER STRIP

The starter strip functions to help shed water off the roof at the eaves and rake areas. By adhering to other shingles, the strip also adds strength to the shingles layer above. The starter strip also provides a nice looking, straight edge at the eave and rake areas.

FASTENERS

Fasteners for asphalt shingles must be galvanized steel, stainless steel, copper or aluminum roofing nails, minimum 12-gauge shank with a minimum 3/8-inch-diameter nail head.

NAIL PENETRATION

The fastener should be long enough to penetrate through the roofing materials, and at least 3/4 of an inch into the roof sheathing. If the sheathing is less than 3/4 of an inch thick, the nail should go through the sheathing.

Observation

It is very difficult to see the fasteners from the other side of the roof sheathing. It may be visible from the attic access area.

SLOPE

Asphalt shingles should be used only on roofs that are 2:12 or greater in slope. Asphalt shingles should not be installed on roofs with slopes less than 2:12. For roof slopes from 2:12 to up to 4:12, a double layer of underlayment should be applied.

Observation

For slopes 2:12 up to 4:12, the underlayment should be two layers applied with a 19-inch strip of underlayment felt parallel to and starting at the eaves. Starting at the eave, applied 36-inch-wide sheets of underlayment, overlapping successive sheets by 19 inches.

For slopes 4:12 or greater, underlayment is one layer applied in a shingle fashion, parallel to and starting from the eave and lapped by 2 inches. End laps should be 4 inches and offset by 6 feet.

Slope vs. Pitch

Home inspectors should use the term "slope" when describing the roof slope. To learn more about the difference between "slope" and "pitch," visit www.nachi.org/roof-slope-pitch.

UNDERLAYMENT

Observation

The underlayment is asphalt saturated organic felt complying with ASTM D-4869 standard. According to 2015 IRC R905.2, the underlayment for asphalt shingle can be ASTM D-4869, Type I, #15 for winds under 140 mph.

For slopes 2:12 up to 4:12, the underlayment should be two layers applied with a 19-inch strip of underlayment felt parallel to and starting at the eaves. Starting at the eave, applied 36-inch-wide sheets of underlayment, overlapping successive sheets by 19 inches.

For slopes 4:12 or greater, underlayment is one layer applied in a shingle fashion, parallel to and starting from the eave and lapped by 2 inches. End laps should be 4 inches and offset by 6 feet.

Observation

The underlayment was not installed properly up the sidewall.

KICK OUT FLASHING

Observation

Kick out flashing missing.

MANUFACTURER'S INSTALLATION

10 STEPS TO PERFORMING A ROOF INSPECTION

There are ten steps to performing a roof inspection on an asphalt shingle roof.