Mastering Roof Inspections: Asphalt Composition Shingles, Part 50

by Kenton Shepard and Nick Gromicko, CMI®

The purpose of the series “Mastering Roof Inspections” is to teach home inspectors, as well as insurance and roofing professionals, how to recognize proper and improper conditions while inspecting steep-slope, residential roofs. This series covers roof framing, roofing materials, the attic, and the conditions that affect the roofing materials and components, including wind and hail.

Many factors affecting wind damage to asphalt shingles also affect other types of roofing materials and are covered in detail in InterNACHI's How to Perform Roofing Inspections course. In this article, we’ll look at additional factors affecting asphalt shingles.

Studies and actual conditions have shown that asphalt shingles are capable of good performance under conditions of high wind, even though they often don’t perform to their capacity. A large part of the problem is due to improper installation practices.

Based on current knowledge, the most important considerations for preventing wind damage, in order of importance, are:

- a fully bonded adhesive strip;

- the correct number of fasteners;

- correct placement of the fasteners; and

- the mechanical properties of the shingles.

Wind-Resistance Standards

Most of the information available today about asphalt shingles' wind resistance comes from research performed in developing manufacturing standards.

Two wind-resistance standards for asphalt shingles have been used in the past: ASTM D 3161 and UL 997.

UL 2390 is widely considered to offer better information. According to this standard, shingles are rated as follows:

- Class D shingles are rated to 90 mph;

- Class G shingles are rated to 120 mph; and

- Class H shingles are rated to 150 mph.

The class that should be installed depends on the exposure in which the home is located.

Although standards for wind resistance have been available since the mid-1960s, you won’t be able to tell whether shingles comply just by looking at them. Some jurisdictions may require new homes to comply with standards that specify a minimum level of wind resistance. The only way to prove compliance is through documentation.

Wind Factors

The wind factors affecting asphalt shingle wind resistance are not constant. Wind varies in intensity, duration, direction and turbulence. Wind damage is also affected by the roof's geometry, with damage usually being worse at the roof's eaves, rakes and ridges. Shingle damage from wind is also affected by the age of the roof, and its temperature at the time of the windstorm.

Failure Modes

Wind damage to shingles generally follows a progression that starts with tab uplift, and can end with shingles being blown off the roof or suffering creased or torn tabs.

Tab Uplift

The wind force that has the greatest effect on shingles is wind that flows within 2 inches of their upper surfaces. As air flows over a shingle, high air pressure is created beneath the leading edge of the tab. At the same time, air that flows over the top creates an area of low pressure. If these two forces together are greater than the combined strength of the adhesive strip, along with the shingle's weight and stiffness, the result is tab uplift.

Once the edge of a tab is lifted, wind forces on the tab are greatly increased, and uplift then happens quickly because the wind suddenly has more exposed surface to push against.

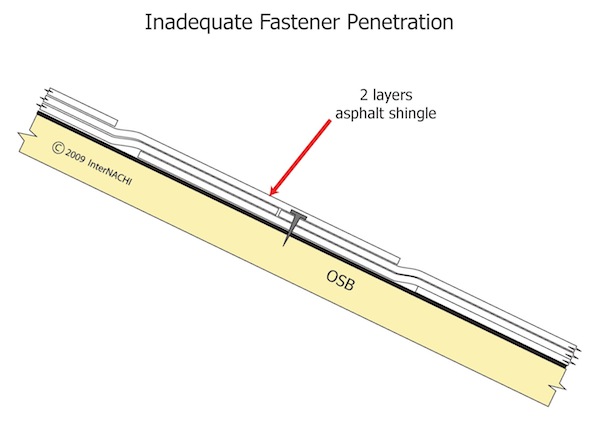

If strip shingles are installed correctly, each fastener penetrates two shingles, and the shingles are fastened along two lines. The first line is just below the adhesive strips, and the second line is near the top of the shingles. If the wind is able to break the bond of the adhesive strip, the tabs will lift and bend upward as the wind tries to pull them over the heads of their fasteners. Also, as the tab is lifted by the wind, the adhesive strip of the shingle in the course above will be stressed by the bending motion.

Shingle Pull-Over

If the shingle pulls over the heads of the lower fasteners, uplift forces on the shingle will increase as the lifting shingle exposes even more surface area upon which the wind can act. Motion this extreme makes it likely that the adhesive strip of the shingle in the course above will be broken.

Creasing and Tearing

**************************************************

Learn how to master a roof inspection from beginning to end by reading the entire InterNACHI series: Mastering Roof Inspections.

Take InterNACHI’s free, online Roofing Inspection Course

Mastering Roof Inspections

Roofing Underlayment Types

Inspecting Underlayment on Roofs

Fall-Arrest Systems

Roofing (consumer-targeted)

More inspection articles like this