Home Inspector Safety & the Dangers of Arc Flashes

The Basics

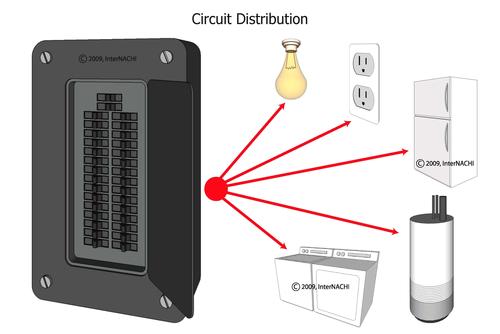

The typical electrical service for homes in North America is a 120/240V split-phase system provided by a pole-mounted distribution transformer located at the service drop, which is made up of two 120-volt lines and a neutral line. This triplex cable may include a messenger cable located in the middle of the neutral conductor that provides support over long spans. The neutral line from the pole is connected to an earth ground near the service panel, which is usually a conductive rod driven into the earth. The service drop provides the home with two 120-volt lines of opposite phase, so 240 volts can be obtained by connecting a load between the two 120-volt conductors, while 120-volt loads are connected between either of the two 120-volt lines and the neutral line. The 240-volt circuit is used for a home’s electrical appliances that require substantial power, such as a furnace, water heater, air conditioner, washer and dryer, and oven/range. The 120-volt circuit is used for lighter electrical loads, such as household lighting, and portable appliances and electronics that are plugged into the home’s standard two- or three-prong (with a grounding wire) electrical receptacles or outlets.

Homes in European countries use three-phase power having longer service drops that can serve multiple residences, which is an economical approach to providing power to dense populations in small areas. This type of service drop consists of three phase wires and one grounded neutral wire.

How an Electrical Circuit Works

Everyone should understand that it’s possible to receive an electrical shock whenever electrical power is present, regardless of the level of power or the presence of any protective devices.

An electrical circuit requires a minimum of two wires through which electric current (in the form of electrons) flows. Current is measured in amperes (amps, for short), which travels from a power source (such as the local utility), through the device it operates, called the load, and then back to the source to complete the circuit. In AC or alternating-current wiring, there are about 120 volts in the “hot” or energized wire. This voltage provides the momentum that forces the electrons to flow in the circuit. The power switches on electrical devices are wired on the hot or “live” side of the circuit. The return conductor, known as the neutral, is at 0 volts because it is grounded at the electrical panel. Most 120-volt circuits are wired to deliver 15 or 20 amps of current.

How Injuries Occur

Modern electrical systems are wired with circuit breakers, or with fuses in older construction. These devices serve as over-current protection and are rated in amps. Most household circuits are wired for 15 or 20 amps. Over-current protection devices are designed to protect the electrical system’s wiring and equipment from overheating, but they may not protect a person from electrical shock, which is why any type of component in the system should be approached with caution.

By coming into contact with a live load or energized wire, a person's body (even a finger) can complete a circuit by connecting the power source with the ground. If this happens, it’s likely that the person will sustain an injury. Most fatal injuries result from high-voltage exposure, but it’s possible to incur a severe injury from low-voltage power if it has a high-current flow. Even if the current isn’t high, a person could be shocked or even electrocuted without ever tripping a circuit breaker or blowing a fuse. Currents of 50 to 100 milliamperes (1 mA = 1/1,000 of 1 amp) can be fatal.

Standards of Practice

According to InterNACHI’s Standards of Practice for Performing a General Home Inspection, the  inspector is not required to:

inspector is not required to:

- measure or determine the amperage or voltage of the main service equipment;

- remove panelboard cabinet covers or dead fronts;

- insert any tool, probe or device into the main panelboard, sub-panels, distribution panelboards, or electrical fixtures; or

- operate any electrical disconnect or over-current protection devices.

Nevertheless, there are warning signs that a panelboard or the system in general may be compromised, and these should persuade the inspector to defer further evaluation to a licensed electrical contractor:

- scorch marks on the dead front or the panelboard door, indicating a past or recent arc flash;

- rust, which indicates past or recent moisture intrusion;

- missing or open breakers that cannot be confirmed to be de-energized;

- overloading of the circuits with DIY wiring;

- uninsulated wiring;

- excessive dust, dirt and debris inside the panelboard; and/or

- any signs of water inside, around or below the panelboard, which can lead to shock or electrocution.

What Is an Arc Flash?

An arc flash occurs when a flashover of electric current leaves its intended path and travels through the air from one conductor to another, or to neutral or ground. It often happens unexpectedly and can be explosive but brief, or it can last seconds and be rather visually spectacular. It can cause a little damage or it can disable a system and require the replacement of equipment. An arc flash of any size is quite dangerous because its path is unpredictable; it will be attracted to the nearest item with the greatest conductivity, such as an unsuspecting rodent or house pet, or a person. An arc flash can cause a serious electrical burn or even fatal electrocution.

An arc flash can have various catalysts, including:

- excess dust;

- condensation;

- corrosion;

- component failure;

- faulty system installation;

- dropping a metal tool, which may cause even a small spark; and/or

- accidental contact.

- proximity;

- temperature; and

- the time it takes for the circuit to break.

An injury due to an arc flash can be quite serious because of the violent nature of such a powerful burst of electrical energy. The light from an arc flash can be blinding and disorienting. The heat caused by an arc flash can be as high as 35,000° F, causing serious contact burns, as well as risk of catching fire. It can create a blast pressure of up to 2,000 pounds per square foot, sending damaged and super-heated electrical components flying through the air like shrapnel, with a sound blast as loud as a gun firing (140 decibels). Combine all these unexpected jolts of sensory overload and the physical consequences can be impossible to avoid.

2. Wear PPE. Regardless of whether you choose to exceed the SOP, always have available and wear the appropriate PPE, including fire-resistant clothing and insulated gloves made specifically for working with electrical equipment. It’s also wise to use protective eyewear. Even a small spark can cause a severe eye injury.

3. Check your surroundings. If there is a lack of ground-fault circuit interrupters (GFCIs), or if there is evidence of a water leak or moisture intrusion, or if the panelboard has scorch marks, potentially indicating a previous arc flash or electrical fire, pay attention to these and other clues, as they may lead you to immediately defer the electrical portion of your home inspection. Again, assess the risk and then decide whether to proceed.4. Use the appropriate tools. According to 3.7.I.I. of InterNACHI's SOP, inspectors are required to:

...test all ground-fault circuit interrupter receptacles and circuit breakers observed and deemed to be GFCIs using a GFCI tester, where possible...

Make sure your tester is working properly before your inspection appointment. An infrared camera is also an excellent tool for detecting hot spots during the electrical inspection.

5. Protect your clients. Many inspectors encourage their clients to accompany them during the inspection so that they can point out important shutoff valves and switches, and discuss maintenance items. However, inspectors should use extreme caution when deciding whether to have the client with them during inspection of the panelboard if signs indicate that it may not be safe. This is true for any area of the home that exhibits signs of instability or some apparent hazard. Using the InterNACHI "Stay Back" Stop Sign (available from Inspector Outlet) can help keep clients, their family members and their realtors away from an inspected area. It’s also useful for limiting the inspector’s liability if the client chooses to ignore your warnings and suffers an injury during the inspection.

5. Protect your clients. Many inspectors encourage their clients to accompany them during the inspection so that they can point out important shutoff valves and switches, and discuss maintenance items. However, inspectors should use extreme caution when deciding whether to have the client with them during inspection of the panelboard if signs indicate that it may not be safe. This is true for any area of the home that exhibits signs of instability or some apparent hazard. Using the InterNACHI "Stay Back" Stop Sign (available from Inspector Outlet) can help keep clients, their family members and their realtors away from an inspected area. It’s also useful for limiting the inspector’s liability if the client chooses to ignore your warnings and suffers an injury during the inspection.

- Arc flashes are just one of the more serious examples of what can go wrong during an inspection, which is why inspectors should follow their training, as well as their instincts, and protect themselves and their clients on the job. It’s always better to be safe than sorry and incur a grievous injury, which can put both your livelihood and life at risk.