Structural Design of Wood Framing for the Home Inspector

by Nick Gromicko, CMI® and Ben Gromicko

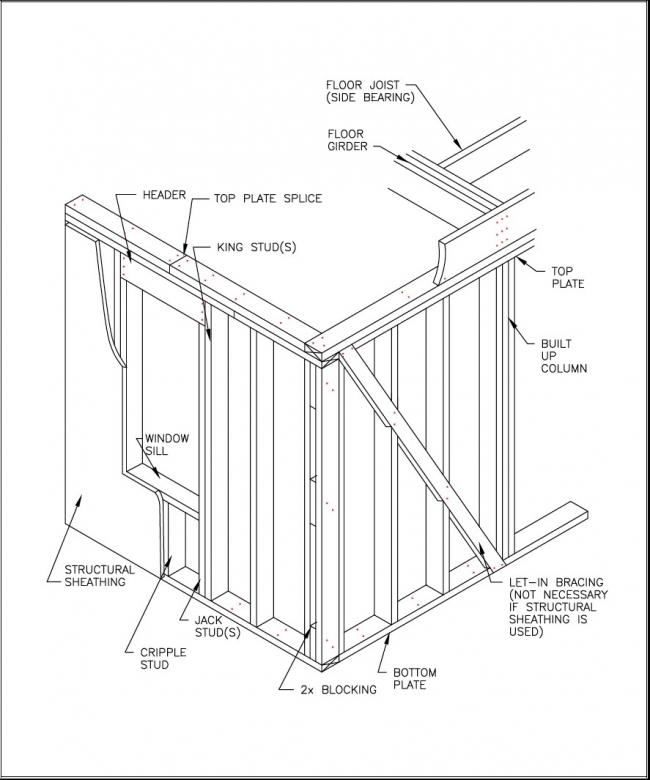

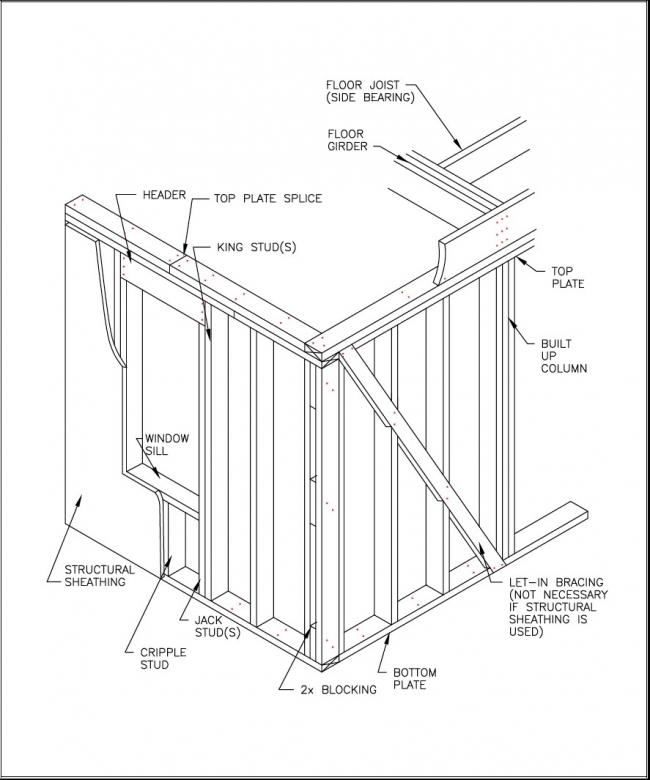

General

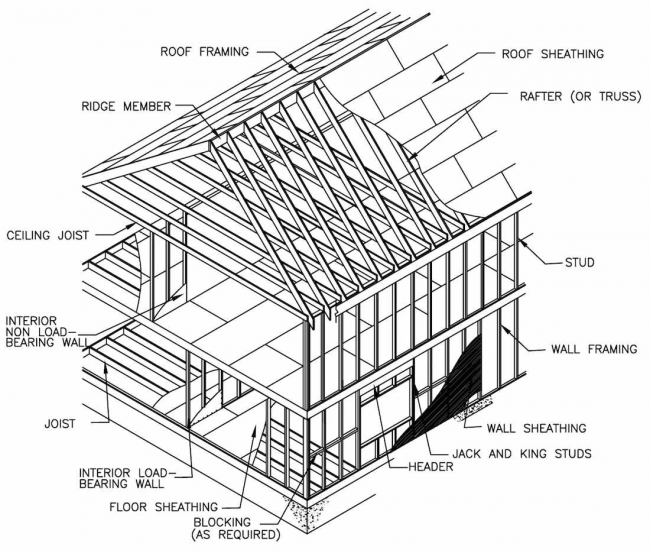

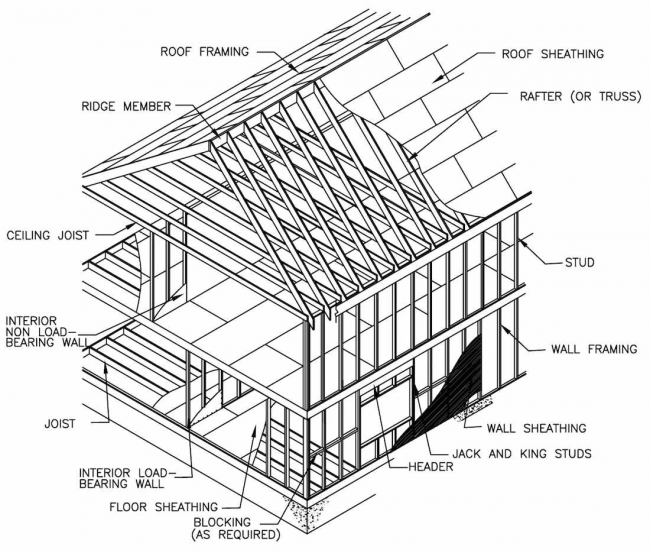

This article addresses elements of above-grade structural systems in residential construction. The residential construction material most commonly used above grade in North America is light-frame wood; therefore, we'll focus on structural design that specifies standard-dimension lumber and structural wood panels (i.e., plywood and oriented strand-board sheathing). Design of the lateral force-resisting system (shear walls and diaphragms) must be approached from a system design perspective. Connections and their importance relative to the overall performance of wood-framed construction cannot be overemphasized. The basic components and assemblies of a conventional wood frame home are shown in Figure 5.1.Many elements of a home work together as a system to resist lateral and axial forces imposed on the above-grade structure and transfer them to the foundation. The above-grade structure also helps resist lateral soil loads on foundation walls through the connection of the floor system to the foundation. Therefore, the issue of system performance is most pronounced in the above-grade assemblies of light-frame homes. Within the context of simple engineering approaches that are familiar to inspectors, system-based design principles are addressed here.

The design of the above-grade structure involves the following structural systems and assemblies:

Wood members that are in contact with the ground should be preservative-treated. The most common lumber treatment is CCA (copper chromium arsenate), which should be used for applications such as sill plates located near the ground and for exterior decks. It is important to specify the correct level of treatment: 0.4 pcf retention for non-ground-contact exterior exposure, and 0.6 pcf for ground contact.

Termites and other wood-destroying insects (e.g., carpenter ants, boring beetles, etc.) attack wood materials. Some practical solutions include: the chemical treatment of soil; the installation of physical barriers (e.g., termite shields); and the specification of treated lumber.

Termites are a special problem in warmer climates, although they also plague many other areas of the United States. The most common termites are subterranean termites that nest in the ground and enter wood that is near or in contact with damp soil. They gain access to above-grade wood through cracks in the foundation or through shelter tubes (mud tunnels) on the surface of foundation walls. Since the presence of termites lends itself to visual detection, wood-framed homes require periodic inspection for signs of termites.

Structural Wood Panels

Historically, boards were used for roof, floor, and wall sheathing; in the last 30 years, however, structural wood panel products have come to dominate the sheathing market. Structural wood panel products are more economical and efficient and can be stronger than traditional board sheathing. Structural wood panel products primarily include plywood and oriented strand board (OSB).

Key to Adjustment Factors:

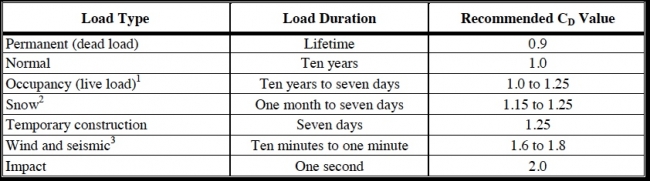

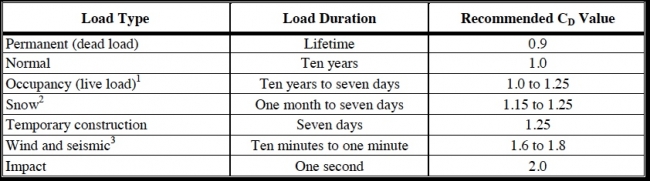

Lumber strength is affected by the cumulative duration of maximum variable loads experienced during the life of the structure. In other words, strength is affected by both the load intensity and its duration (i.e., the load history). Because of its natural composition, wood is better able to resist higher short-term loads (i.e., transient live loads or impact loads) than long-term loads (i.e., dead loads and sustained live loads). Under impact loading, wood can resist about twice as much stress as the standard 10-year load duration (i.e., normal duration) to which wood bending stress properties are normalized in the NDS.

When other loads with different duration characteristics are considered, it is necessary to modify certain tabulated stresses by a load duration factor (CD) as shown in Table 5.3. Values of the load duration factor, CD, for various load types are based on the total accumulated time effects of a given type of load during the useful life of a structure. CD increases with decreasing load duration.

Where more than one load type is specified in a design analysis, the load duration factor associated with the shortest duration load is applied to the entire combination of loads.

The design of the above-grade structure involves the following structural systems and assemblies:

- floors;

- walls; and

- roofs.

Each system can be complex to design as a whole; therefore, simple analysis usually focuses on the individual elements that constitute the system. In some cases, “system effects” may be considered in simplified form and applied to the design of certain elements that constitute specifically defined systems.

Structural elements that make up a residential structural system include:

Let's look at the NDS equations in general, which includes design examples that detail the appropriate use of the equations for specific structural elements or systems in light, wood-framed construction, focusing primarily on framing with traditional dimensional lumber, giving some consideration to common engineered wood products. Other wood framing methods, such as post-and-beam construction, are not explicitly addressed here, although much of the information is relevant. However, system considerations and system factors presented here are only relevant to light, wood-framed construction using dimensional lumber.

Regardless of the type of structural element, the inspector must first determine nominal design loads. The loads acting on a framing member or system are usually calculated in accordance with the applicable provisions of the locally approved building code and engineering standards.

While prescriptive design tables or span tables and similar design aids commonly used in residential applications are not included herein, the inspector may save considerable effort by consulting such resources. Most local, state or national model building codes, such as The One- and Two-Family Dwelling Code (ICC), contain prescriptive design and construction provisions for conventional residential construction. For high-wind conditions, prescriptive guidelines for design and construction may be found in the Wood-Frame Construction Manual for One- and Two-Family Dwellings (AFPA). The inspector is also encouraged to obtain design data on a variety of proprietary engineered-wood products that are suitable for many special design needs in residential construction. However, these materials generally should not be viewed as simple one-to-one substitutes for conventional wood framing, and any special design and construction requirements should be carefully considered in accordance with the manufacturer’s recommendation or applicable code evaluation reports.

Material Properties

It is essential that a residential inspector specifying wood materials appreciate the natural characteristics of wood and their effect on the engineering properties of lumber. A brief discussion of the properties of lumber and structural wood panels follows.

Lumber

General

As with all materials, the inspector must consider wood’s strengths and weaknesses. A comprehensive source of technical information on the characteristics of wood is the Wood Engineering Handbook, Second Edition (Forest Products Laboratory). For the most part, the knowledge embodied in the handbook is reflected in the provisions of the NDS and the NDS Supplement (NDS-S) design data; however, many aspects of wood design require good judgment.

Wood is a natural substance that, as a structural material, demonstrates unique and complex characteristics. Wood’s structural properties can be traced back to its natural composition. Wood is foremost a non-homogeneous, non-isotropic material, and thus exhibits different structural properties, depending on the orientation of stresses relative to the grain of the wood. The grain is produced by the tree’s annual growth rings, which determine the properties of the wood along three orientations: tangential, radial and longitudinal.

Given that lumber is cut from logs in a longitudinal direction, the grain is parallel to the length of the lumber member. Depending on where the lumber is cut relative to the center of a log (i.e., tangential versus radial), properties vary across the width and thickness of an individual member.

Wood Species

Structural lumber can be manufactured from a variety of wood species; however, the various species used in a given locality are a function of the economy, regional availability, and required strength properties. A wood species is classified as either hardwood or softwood. Hardwoods are broad-leafed deciduous trees, while softwoods (i.e., conifers) are trees with needle-like leaves and are generally evergreen.

Most structural lumber is manufactured from softwoods because of the trees’ faster growth rate, availability, and workability (i.e., ease of cutting, nailing, etc.). A wood species is further classified into groups or combinations as defined in the NDS. Species within a group have similar properties and are subject to the same grading rules. Douglas fir-larch, southern yellow pine, hem-fir, and spruce-pine-fir are species groups that are widely used in residential applications in the United States.

Lumber Sizes

Wood members are referred to by nominal sizes (e.g., 2x4); however, true dimensions are somewhat less. The difference occurs during the dressing stage of the lumber process, when each surface of the member is planed to its final dressed dimension after shrinkage has occurred as a result of the drying or seasoning process. Generally, there is a 1/4- to 3/4-inch difference between the nominal and dressed sizes of dry-sawn lumber (refer to NDS-S Table 1B for specific dimensions). For example, a 2x4 is actually 1.5 inches by 3.5 inches, a 2x10 is 1.5 inches by 9.25 inches, and a 1x4 is 3/4-inch by 3.5 inches. This guide uses nominal member size, but it is important to note that the inspector must apply the actual dimensions of the lumber when analyzing structural performance or detailing construction dimensions.

Based on the expected application, the tabulated values in the NDS are classified by the species of wood as well as by the nominal size of a member.

- bending members;

- columns;

- combined bending and axial loaded members;

- sheathing (i.e., diaphragm); and

- connections.

Let's look at the NDS equations in general, which includes design examples that detail the appropriate use of the equations for specific structural elements or systems in light, wood-framed construction, focusing primarily on framing with traditional dimensional lumber, giving some consideration to common engineered wood products. Other wood framing methods, such as post-and-beam construction, are not explicitly addressed here, although much of the information is relevant. However, system considerations and system factors presented here are only relevant to light, wood-framed construction using dimensional lumber.

Regardless of the type of structural element, the inspector must first determine nominal design loads. The loads acting on a framing member or system are usually calculated in accordance with the applicable provisions of the locally approved building code and engineering standards.

While prescriptive design tables or span tables and similar design aids commonly used in residential applications are not included herein, the inspector may save considerable effort by consulting such resources. Most local, state or national model building codes, such as The One- and Two-Family Dwelling Code (ICC), contain prescriptive design and construction provisions for conventional residential construction. For high-wind conditions, prescriptive guidelines for design and construction may be found in the Wood-Frame Construction Manual for One- and Two-Family Dwellings (AFPA). The inspector is also encouraged to obtain design data on a variety of proprietary engineered-wood products that are suitable for many special design needs in residential construction. However, these materials generally should not be viewed as simple one-to-one substitutes for conventional wood framing, and any special design and construction requirements should be carefully considered in accordance with the manufacturer’s recommendation or applicable code evaluation reports.

Material Properties

It is essential that a residential inspector specifying wood materials appreciate the natural characteristics of wood and their effect on the engineering properties of lumber. A brief discussion of the properties of lumber and structural wood panels follows.

Lumber

General

As with all materials, the inspector must consider wood’s strengths and weaknesses. A comprehensive source of technical information on the characteristics of wood is the Wood Engineering Handbook, Second Edition (Forest Products Laboratory). For the most part, the knowledge embodied in the handbook is reflected in the provisions of the NDS and the NDS Supplement (NDS-S) design data; however, many aspects of wood design require good judgment.

Wood is a natural substance that, as a structural material, demonstrates unique and complex characteristics. Wood’s structural properties can be traced back to its natural composition. Wood is foremost a non-homogeneous, non-isotropic material, and thus exhibits different structural properties, depending on the orientation of stresses relative to the grain of the wood. The grain is produced by the tree’s annual growth rings, which determine the properties of the wood along three orientations: tangential, radial and longitudinal.

Given that lumber is cut from logs in a longitudinal direction, the grain is parallel to the length of the lumber member. Depending on where the lumber is cut relative to the center of a log (i.e., tangential versus radial), properties vary across the width and thickness of an individual member.

Wood Species

Structural lumber can be manufactured from a variety of wood species; however, the various species used in a given locality are a function of the economy, regional availability, and required strength properties. A wood species is classified as either hardwood or softwood. Hardwoods are broad-leafed deciduous trees, while softwoods (i.e., conifers) are trees with needle-like leaves and are generally evergreen.

Most structural lumber is manufactured from softwoods because of the trees’ faster growth rate, availability, and workability (i.e., ease of cutting, nailing, etc.). A wood species is further classified into groups or combinations as defined in the NDS. Species within a group have similar properties and are subject to the same grading rules. Douglas fir-larch, southern yellow pine, hem-fir, and spruce-pine-fir are species groups that are widely used in residential applications in the United States.

Lumber Sizes

Wood members are referred to by nominal sizes (e.g., 2x4); however, true dimensions are somewhat less. The difference occurs during the dressing stage of the lumber process, when each surface of the member is planed to its final dressed dimension after shrinkage has occurred as a result of the drying or seasoning process. Generally, there is a 1/4- to 3/4-inch difference between the nominal and dressed sizes of dry-sawn lumber (refer to NDS-S Table 1B for specific dimensions). For example, a 2x4 is actually 1.5 inches by 3.5 inches, a 2x10 is 1.5 inches by 9.25 inches, and a 1x4 is 3/4-inch by 3.5 inches. This guide uses nominal member size, but it is important to note that the inspector must apply the actual dimensions of the lumber when analyzing structural performance or detailing construction dimensions.

Based on the expected application, the tabulated values in the NDS are classified by the species of wood as well as by the nominal size of a member.

Typical NDS classifications follow:

Lumber Grades

Lumber is graded in accordance with standardized grading rules that consider the effect of natural growth characteristics and defects, such as knots and angle of grain, on the member’s structural properties. Growth characteristics reduce the overall strength of the member relative to a “perfect,” clear-grained member without any natural defects. Most lumber is visually graded, although it can also be machine stress-rated or machine-evaluated.

Visually graded lumber is graded by an individual who examines the wood member at the mill in accordance with an approved agency’s grading rules. The grader separates wood members into the appropriate grade classes. Typical visual grading classes, in order of decreasing strength properties, are Select Structural, No. 1, No. 2, Stud, etc. Refer to the NDS Supplement (NDS-S) for more information on grades of different species of lumber. The inspector should consult a lumber supplier or contractor regarding locally available lumber species and grades.

Machine stress-rated (MSR) and machine-evaluated lumber (MEL) are subjected to non-destructive testing of each piece. The wood member is then marked with the appropriate grade stamp, which includes the allowable bending stress (Fb) and the modulus of elasticity (E). This grading method yields lumber with more consistent structural properties than visual grading only.

While grading rules vary among grading agencies, the U.S. Department of Commerce has set forth minimums for voluntary adoption by the recognized lumber grading agencies. For more information regarding grading rules, refer to the American Softwood Lumber Voluntary Product Standard, which is maintained by the National Institute for Standards and Technology (NIST). NDS-S lists approved grading agencies and roles.

Moisture Content

Wood properties and dimensions change with moisture content (MC). Living wood contains a considerable amount of free and bound water. Free water is contained between the wood cells and is the first water to be driven off in the drying process. Its loss affects neither volume nor structural properties. Bound water is contained within the wood cells and accounts for most of the moisture under 30%; its loss results in changes in both volume (i.e., shrinkage) and structural properties. The strength of wood peaks at about 10 to 15% MC.

Given that wood generally has an MC of more than 30% when cut and may dry to an equilibrium moisture content (EMC) of 8 to 10% in a protected environment, it should be sufficiently dried or seasoned before installation. Proper drying and storage of lumber minimizes problems associated with lumber shrinkage and warping. A minimum recommendation calls for using surface-dry lumber with a maximum 19% MC. In uses where shrinkage is critical, specifications may call for KD-15, which is kiln-dried lumber with a maximum moisture content of 15%. The tabulated design values in the NDS are based on a moisture content of 19% for dimensional lumber.

The inspector should plan for the vertical movement that may occur in a structure as a result of shrinkage. For more complicated structural details that call for various types of materials and systems, the inspector might have to account for differential shrinkage by isolating members that will shrink from those that will maintain dimensional stability. The inspector should also detail the structure such that shrinkage is as uniform as possible, thereby minimizing shrinkage effects on finish surfaces. When practical, details that minimize the amount of wood transferring loads perpendicular-to-grain are preferable.

Shrinking and swelling can be estimated for the width and thickness of wood members (i.e., tangentially and radially, with respect to annual rings). Shrinkage in the longitudinal direction of a wood member (parallel to the grain) is negligible.

Durability

Moisture is a primary factor affecting the durability of lumber. Fungi, which feed on wood cells, require moisture, air, and favorable temperatures to survive. When wood is subject to moisture levels above 20% and other favorable conditions, decay begins to set in.

- Boards are less than 2 inches thick.

- Dimensional lumber is a minimum of 2 inches wide and 2 to 4 inches thick.

- Beams and stringers are a minimum of 5 inches thick, with the width at least 2 inches greater than the thickness dimension.

- Posts and timbers are a minimum of 5 inches thick, and the width does not exceed the thickness by more than 2 inches.

- Decking is 2 to 4 inches thick and loaded in the weak axis of bending for a roof, floor or wall surface.

Lumber Grades

Lumber is graded in accordance with standardized grading rules that consider the effect of natural growth characteristics and defects, such as knots and angle of grain, on the member’s structural properties. Growth characteristics reduce the overall strength of the member relative to a “perfect,” clear-grained member without any natural defects. Most lumber is visually graded, although it can also be machine stress-rated or machine-evaluated.

Visually graded lumber is graded by an individual who examines the wood member at the mill in accordance with an approved agency’s grading rules. The grader separates wood members into the appropriate grade classes. Typical visual grading classes, in order of decreasing strength properties, are Select Structural, No. 1, No. 2, Stud, etc. Refer to the NDS Supplement (NDS-S) for more information on grades of different species of lumber. The inspector should consult a lumber supplier or contractor regarding locally available lumber species and grades.

Machine stress-rated (MSR) and machine-evaluated lumber (MEL) are subjected to non-destructive testing of each piece. The wood member is then marked with the appropriate grade stamp, which includes the allowable bending stress (Fb) and the modulus of elasticity (E). This grading method yields lumber with more consistent structural properties than visual grading only.

While grading rules vary among grading agencies, the U.S. Department of Commerce has set forth minimums for voluntary adoption by the recognized lumber grading agencies. For more information regarding grading rules, refer to the American Softwood Lumber Voluntary Product Standard, which is maintained by the National Institute for Standards and Technology (NIST). NDS-S lists approved grading agencies and roles.

Moisture Content

Wood properties and dimensions change with moisture content (MC). Living wood contains a considerable amount of free and bound water. Free water is contained between the wood cells and is the first water to be driven off in the drying process. Its loss affects neither volume nor structural properties. Bound water is contained within the wood cells and accounts for most of the moisture under 30%; its loss results in changes in both volume (i.e., shrinkage) and structural properties. The strength of wood peaks at about 10 to 15% MC.

Given that wood generally has an MC of more than 30% when cut and may dry to an equilibrium moisture content (EMC) of 8 to 10% in a protected environment, it should be sufficiently dried or seasoned before installation. Proper drying and storage of lumber minimizes problems associated with lumber shrinkage and warping. A minimum recommendation calls for using surface-dry lumber with a maximum 19% MC. In uses where shrinkage is critical, specifications may call for KD-15, which is kiln-dried lumber with a maximum moisture content of 15%. The tabulated design values in the NDS are based on a moisture content of 19% for dimensional lumber.

The inspector should plan for the vertical movement that may occur in a structure as a result of shrinkage. For more complicated structural details that call for various types of materials and systems, the inspector might have to account for differential shrinkage by isolating members that will shrink from those that will maintain dimensional stability. The inspector should also detail the structure such that shrinkage is as uniform as possible, thereby minimizing shrinkage effects on finish surfaces. When practical, details that minimize the amount of wood transferring loads perpendicular-to-grain are preferable.

Shrinking and swelling can be estimated for the width and thickness of wood members (i.e., tangentially and radially, with respect to annual rings). Shrinkage in the longitudinal direction of a wood member (parallel to the grain) is negligible.

Durability

Moisture is a primary factor affecting the durability of lumber. Fungi, which feed on wood cells, require moisture, air, and favorable temperatures to survive. When wood is subject to moisture levels above 20% and other favorable conditions, decay begins to set in.

Therefore, it is important to protect wood materials from moisture, by:

• limiting end use (e.g., specifying interior applications or isolating lumber from ground contact);

• using a weather barrier (e.g., siding, roofing, building wrap, flashing, etc.);

• applying a protective coating (e.g., paint, water repellent, etc.);

• installing roof overhangs and gutters; and

• specifying preservative-treated or naturally decay-resistant wood.

For homes, an exterior weather barrier (e.g., roofing and siding) protects most structural wood. However, improper detailing can lead to moisture intrusion and decay. Problems are commonly associated with improper or missing flashing and undue reliance on caulking to prevent moisture intrusion. For additional information and guidance on improving the durability of wood in buildings, refer to Prevention and Control of Decay in Homes (HUD).

• limiting end use (e.g., specifying interior applications or isolating lumber from ground contact);

• using a weather barrier (e.g., siding, roofing, building wrap, flashing, etc.);

• applying a protective coating (e.g., paint, water repellent, etc.);

• installing roof overhangs and gutters; and

• specifying preservative-treated or naturally decay-resistant wood.

For homes, an exterior weather barrier (e.g., roofing and siding) protects most structural wood. However, improper detailing can lead to moisture intrusion and decay. Problems are commonly associated with improper or missing flashing and undue reliance on caulking to prevent moisture intrusion. For additional information and guidance on improving the durability of wood in buildings, refer to Prevention and Control of Decay in Homes (HUD).

Wood members that are in contact with the ground should be preservative-treated. The most common lumber treatment is CCA (copper chromium arsenate), which should be used for applications such as sill plates located near the ground and for exterior decks. It is important to specify the correct level of treatment: 0.4 pcf retention for non-ground-contact exterior exposure, and 0.6 pcf for ground contact.

Termites and other wood-destroying insects (e.g., carpenter ants, boring beetles, etc.) attack wood materials. Some practical solutions include: the chemical treatment of soil; the installation of physical barriers (e.g., termite shields); and the specification of treated lumber.

Termites are a special problem in warmer climates, although they also plague many other areas of the United States. The most common termites are subterranean termites that nest in the ground and enter wood that is near or in contact with damp soil. They gain access to above-grade wood through cracks in the foundation or through shelter tubes (mud tunnels) on the surface of foundation walls. Since the presence of termites lends itself to visual detection, wood-framed homes require periodic inspection for signs of termites.

Structural Wood Panels

Historically, boards were used for roof, floor, and wall sheathing; in the last 30 years, however, structural wood panel products have come to dominate the sheathing market. Structural wood panel products are more economical and efficient and can be stronger than traditional board sheathing. Structural wood panel products primarily include plywood and oriented strand board (OSB).

Plywood is manufactured from wood veneers glued together under high temperature and pressure. Each veneer or ply is placed with its grain perpendicular to the grain of the previous layer. The outer layers are placed with their grain parallel to the longer dimension of the panel. Thus, plywood is stronger in bending along the long direction and should be placed with the long dimension spanning floor and roof framing members. The number of plies typically ranges from three to five. Oriented strand board is manufactured from thin wood strands glued together under high temperature and pressure. The strands are layered and oriented to produce strength properties similar to plywood; therefore, the material is used for the same applications as plywood.

The inspector should specify the grade and span rating of structural wood panels to meet the required application and loading condition (i.e., roof, wall or floor). The most common panel size is 4x8-foot panels, with thicknesses typically ranging from 3/8-inch to more than 1 inch. Panels can be ordered in longer lengths for special applications.

Plywood is performance-rated for industrial and construction plywood. OSB products are performance-rated. However, these standards are voluntary, and not all wood-based panel products are rated accordingly. The rating system of the APA-Engineered Wood Association (formerly the American Plywood Association) for structural wood panel sheathing products and those used by other structural panel trademarking organizations are based on the U.S. Department of Commerce's voluntary product standards.

The veneer grade of plywood is associated with the veneers used on the exposed faces of a panel as follows:

Lumber Design Values

The NDS-S provides tabulated design stress values for bending, tension parallel to grain, shear parallel to grain, compression parallel and perpendicular to grain, and modulus of elasticity. In particular, NDS includes the most up-to-date design values based on test results from an eight-year, full-scale testing program that used lumber samples from mills across the United States and Canada.

Characteristic structural properties for use in allowable stress design and load and resistance factor design are used to establish design values. Test data collected in accordance with the applicable standards determine a characteristic strength value for each grade and species of lumber. The value is usually the mean (average) or 5th-percentile test value. The 5th percentile represents the value that 95% of the sampled members exceeded. In ASD, characteristic structural values are multiplied by the reduction factors in Table 5.1. The reduction factors are implicit in the allowable values published in the NDS-S for standardized conditions. The reduction factor normalizes the lumber properties to a standard set of conditions related to load duration, moisture content, and other factors. It also includes a safety adjustment (if applicable) to the particular limit state (i.e., ultimate capacity). Therefore, for specific design conditions that differ from the standard basis, design property values should be adjusted.

The reduction factors in Table 5.1 are derived as follows, as reported in ASTM D2915 (ASTM):

The allowable values published in the NDS-S are determined for a standard set of conditions. Yet, given the many variations in the characteristics of wood that affect the material’s structural properties, several adjustment factors are available to modify the published values. For efficient design, it is important to use the appropriate adjustments for conditions that vary from those used to derive the standard design values. Table 5.2 presents adjustment factors that apply to different structural properties of wood.

TABLE 5.1 Design Properties and Associated Reduction Factors for ASD

TABLE 5.2 Adjustment Factor Applicability to Design Values for Wood

Plywood is performance-rated for industrial and construction plywood. OSB products are performance-rated. However, these standards are voluntary, and not all wood-based panel products are rated accordingly. The rating system of the APA-Engineered Wood Association (formerly the American Plywood Association) for structural wood panel sheathing products and those used by other structural panel trademarking organizations are based on the U.S. Department of Commerce's voluntary product standards.

The veneer grade of plywood is associated with the veneers used on the exposed faces of a panel as follows:

- Grade A: the highest-quality veneer grade, which is intended for cabinet or furniture use;

- Grade B: a high-quality veneer grade, which is intended for cabinet or furniture use, with all defects repaired;

- Grade C: the minimum veneer grade, which is intended for exterior use; and

- Grade D: the lowest-quality veneer grade, which is intended for interior use or where protected from exposure to weather.

- Exterior panels are designed for applications with permanent exposure to the weather or moisture.

- Exposure 1 panels are designed for applications where temporary exposure to the weather due to construction sequence may be expected.

- Exposure 2 panels are designed for applications with a potential for high humidity or wetting, but are generally protected during construction.

- Interior panels are designed for interior applications only.

Lumber Design Values

The NDS-S provides tabulated design stress values for bending, tension parallel to grain, shear parallel to grain, compression parallel and perpendicular to grain, and modulus of elasticity. In particular, NDS includes the most up-to-date design values based on test results from an eight-year, full-scale testing program that used lumber samples from mills across the United States and Canada.

Characteristic structural properties for use in allowable stress design and load and resistance factor design are used to establish design values. Test data collected in accordance with the applicable standards determine a characteristic strength value for each grade and species of lumber. The value is usually the mean (average) or 5th-percentile test value. The 5th percentile represents the value that 95% of the sampled members exceeded. In ASD, characteristic structural values are multiplied by the reduction factors in Table 5.1. The reduction factors are implicit in the allowable values published in the NDS-S for standardized conditions. The reduction factor normalizes the lumber properties to a standard set of conditions related to load duration, moisture content, and other factors. It also includes a safety adjustment (if applicable) to the particular limit state (i.e., ultimate capacity). Therefore, for specific design conditions that differ from the standard basis, design property values should be adjusted.

The reduction factors in Table 5.1 are derived as follows, as reported in ASTM D2915 (ASTM):

- Fb reduction factor = (10/16 load-duration factor)(10/13 safety factor);

- Ft reduction factor = (10/16 load-duration factor)(10/13 safety factor);

- Fv reduction factor = (10/16 load-duration factor)(4/9 stress-concentration factor)(8/9 safety factor);

- Fc reduction factor = (2/3 load-duration factor)(4/5 safety factor); and

- Fc⊥ reduction factor = (2/3 end-position factor).

Adjustment Factors

The allowable values published in the NDS-S are determined for a standard set of conditions. Yet, given the many variations in the characteristics of wood that affect the material’s structural properties, several adjustment factors are available to modify the published values. For efficient design, it is important to use the appropriate adjustments for conditions that vary from those used to derive the standard design values. Table 5.2 presents adjustment factors that apply to different structural properties of wood.

TABLE 5.1 Design Properties and Associated Reduction Factors for ASD

TABLE 5.2 Adjustment Factor Applicability to Design Values for Wood

Key to Adjustment Factors:

- CD, Load Duration Factor, applies when loads are other than the normal 10-year duration.

- Cr, Repetitive Member Factor, applies to bending members in assemblies with multiple members spaced at maximum 24 inches on center.

- CH, Horizontal Shear Factor, applies to individual or multiple members with regard to horizontal, parallel-to-grain splitting.

- CF, Size Factor, applies to member sizes/grades other than standard test specimens, but does not apply to southern yellow pine.

- CP, Column Stability Factor, applies to lateral support condition of compression members.

- CL, Beam Stability Factor, applies to bending members not subject to continuous lateral support on the compression edge.

- CM, Wet Service Factor, applies where the moisture content is expected to exceed 19% for extended periods.

- Cfu, Flat Use Factor, applies where dimensional lumber 2 to 4 inches thick is subject to a bending load in its weak axis direction.

- Cb, Bearing Area Factor, applies to members with bearing less than 6 inches and not nearer than 3 inches from the members’ ends.

- CT, Buckling Stiffness Factor, applies only to maximum 2x4 dimensional lumber in the top chord of wood trusses that are subjected to combined flexure and axial compression.

- CV, Volume Factor, applies to Glulam® bending members loaded perpendicular to the wide face of the laminations in strong axis bending.

- Ct, Temperature Factor, applies where temperatures exceed 100° F for long periods; not normally required when wood members are subjected to intermittent higher temperatures, such as in roof structures.

- Ci, Incising Factor, applies where structural-sawn lumber is incised to increase penetration of preservatives with small incisions cut parallel to the grain.

- Cc, Curvature Factor, applies only to curved portions of glued, laminated bending members.

- Cf, Form Factor, applies where bending members are either round or square with diagonal loading.

Lumber strength is affected by the cumulative duration of maximum variable loads experienced during the life of the structure. In other words, strength is affected by both the load intensity and its duration (i.e., the load history). Because of its natural composition, wood is better able to resist higher short-term loads (i.e., transient live loads or impact loads) than long-term loads (i.e., dead loads and sustained live loads). Under impact loading, wood can resist about twice as much stress as the standard 10-year load duration (i.e., normal duration) to which wood bending stress properties are normalized in the NDS.

When other loads with different duration characteristics are considered, it is necessary to modify certain tabulated stresses by a load duration factor (CD) as shown in Table 5.3. Values of the load duration factor, CD, for various load types are based on the total accumulated time effects of a given type of load during the useful life of a structure. CD increases with decreasing load duration.

Where more than one load type is specified in a design analysis, the load duration factor associated with the shortest duration load is applied to the entire combination of loads.

For example, for the load combination, Dead Load + Snow Load + Wind Load, the load duration factor, CD, is equal to 1.6.

TABLE 5.3 Recommended Load Duration Factors for ASD

Repetitive Member Factor (Cr)

When three or more parallel dimensional lumber members are spaced a maximum of 24 inches on center and connected with structural sheathing, they comprise a structural system with more bending capacity than the sum of the single members acting individually. Therefore, most elements in a house structure benefit from an adjustment for the system strength effects inherent in repetitive members.

The tabulated design values given in the NDS are based on single members; thus, an increase in allowable stress is permitted in order to account for repetitive members. While the NDS recommends a repetitive member factor of 1.15 or a 15% increase in bending strength, system assembly tests have demonstrated that the NDS repetitive member factor is conservative for certain conditions. In fact, test results from several studies support the range of repetitive member factors shown in Table 5.4 for certain design applications. As shown in Table 5.2, the adjustment factor applies only to extreme fiber in bending, Fb.

TABLE 5.4 Recommended Repetitive Member Factors for Dimension Lumber Used in Framing Systems

With the exception of the 1.15 repetitive member factor, the NDS does not currently recognize the values in Table 5.4. Therefore, the values in Table 5.4 are provided for use by the inspector as an alternative method based on various sources of technical information, including certain standards, code recognized guidelines, and research studies.

Horizontal Shear Factor (CH)

Given that lumber does not dry uniformly, it is subject to warping, checking and splitting, all of which reduce the strength of a member. The horizontal stress values in the NDS-S conservatively account for any checks and splits that may form during the seasoning process and, as in the worst-case values, assume substantial horizontal splits in all wood members. Although a horizontal split may occur in some members, all members in a repetitive member system rarely experience such splits. Therefore, a CH of greater than 1 should typically apply when repetitive framing or built-up members are used. For members with no splits, CH equals 2.

In addition, future allowable horizontal shear values will be increased by a factor of 2 or more because of a recent change in the applicable standard regarding assignment of strength properties. The change is a result of removing a conservative adjustment to the test data whereby a 50% reduction for checks and splits was applied in addition to a 4/9 stress concentration factor, as described in Section 5.2.3. As an interim solution, a shear adjustment factor, CH, of 2 should therefore apply to all designs that use horizontal shear values in 1997 and earlier editions of the NDS. As shown in Table 5.2, the CH factor applies only to the allowable horizontal shear stress, Fv. As an interim consideration regarding horizontal shear at notches and connections in members, a CH value of 1.5 is recommended for use with provisions in NDS•3.4.4 and 3.4.5 for dimensional lumber only.

Size Factor (CF)

Tabulated design values in the NDS-S are based on testing conducted on members of certain sizes. The specified depth for dimensional lumber members subjected to testing is 12 inches for No. 3 or better, 6 inches for stud-grade members, and 4 inches for construction-, standard- or utility-grade members (i.e., CF=1.0).

The size of a member affects unit strength because of the member’s relationship to the likelihood of naturally occurring defects in the material. Therefore, an adjustment to certain tabulated values is appropriate for sizes other than those tested; however, the tabulated values for southern yellow pine have already been adjusted for size and do not require application of CF. Table 5.2 indicates the tabulated values that should be adjusted to account for size differences. The adjustment applies when visually graded lumber is 2 to 4 inches thick or when a minimum 5-inch-thick rectangular bending member exceeds 12 inches in depth. Refer to NDS-S for the appropriate size adjustment factor.

Column Stability Factor (CP)

Tabulated compression design values in the NDS-S are based on the assumption that a compression member is continuously supported along its length to prevent lateral displacement in both the weak and strong axes. When a compression member is subject to continuous lateral support in at least two orthogonal directions, Euler buckling cannot occur. However, many compression members (e.g., interior columns or wall framing) do not have continuous lateral support in two directions.

The column stability factor, CP, adjusts the tabulated compression stresses to account for the possibility of column buckling. For rectangular or non-symmetric columns, CP must be determined for both the weak- and strong-axis bracing conditions. CP is based on end-fixity, effective length of the member between lateral braces, and the cross-sectional dimensions of the member that affect the slenderness ratio used in calculating the critical buckling stress. Given that the Euler buckling effect is associated only with axial loads, the CP factor applies to the allowable compressive stress parallel to grain, Fc, as shown in Table 5.2.

Beam Stability Factor (CL)

The tabulated bending design values, Fb, given in the NDS-S are applicable to bending members that are either braced against lateral-torsional buckling (i.e., twisting) or stable without bracing (i.e., the depth is no greater than the breadth of the member). Most bending members in residential construction are laterally supported on the compression edge by some type of sheathing product. The beam stability factor does, however, apply to conditions such as ceiling joists supporting unfinished attic space. When a member does not meet the lateral support requirements of NDS 3.3.3 or the stability requirements of NDS 4.4.1, the inspector should modify the tabulated bending design values by using the beam stability factor, CL, to account for the possibility of lateral-torsional buckling. For glued laminated timber bending members, the volume factor (CV) and beam stability factor (CL) are not applied simultaneously; thus, the lesser of these factors applies. Refer to the NDS 3.3.3 for the equations used to calculate CL.

Structural Evaluation

TABLE 5.3 Recommended Load Duration Factors for ASD

Repetitive Member Factor (Cr)

When three or more parallel dimensional lumber members are spaced a maximum of 24 inches on center and connected with structural sheathing, they comprise a structural system with more bending capacity than the sum of the single members acting individually. Therefore, most elements in a house structure benefit from an adjustment for the system strength effects inherent in repetitive members.

The tabulated design values given in the NDS are based on single members; thus, an increase in allowable stress is permitted in order to account for repetitive members. While the NDS recommends a repetitive member factor of 1.15 or a 15% increase in bending strength, system assembly tests have demonstrated that the NDS repetitive member factor is conservative for certain conditions. In fact, test results from several studies support the range of repetitive member factors shown in Table 5.4 for certain design applications. As shown in Table 5.2, the adjustment factor applies only to extreme fiber in bending, Fb.

TABLE 5.4 Recommended Repetitive Member Factors for Dimension Lumber Used in Framing Systems

With the exception of the 1.15 repetitive member factor, the NDS does not currently recognize the values in Table 5.4. Therefore, the values in Table 5.4 are provided for use by the inspector as an alternative method based on various sources of technical information, including certain standards, code recognized guidelines, and research studies.

Horizontal Shear Factor (CH)

Given that lumber does not dry uniformly, it is subject to warping, checking and splitting, all of which reduce the strength of a member. The horizontal stress values in the NDS-S conservatively account for any checks and splits that may form during the seasoning process and, as in the worst-case values, assume substantial horizontal splits in all wood members. Although a horizontal split may occur in some members, all members in a repetitive member system rarely experience such splits. Therefore, a CH of greater than 1 should typically apply when repetitive framing or built-up members are used. For members with no splits, CH equals 2.

In addition, future allowable horizontal shear values will be increased by a factor of 2 or more because of a recent change in the applicable standard regarding assignment of strength properties. The change is a result of removing a conservative adjustment to the test data whereby a 50% reduction for checks and splits was applied in addition to a 4/9 stress concentration factor, as described in Section 5.2.3. As an interim solution, a shear adjustment factor, CH, of 2 should therefore apply to all designs that use horizontal shear values in 1997 and earlier editions of the NDS. As shown in Table 5.2, the CH factor applies only to the allowable horizontal shear stress, Fv. As an interim consideration regarding horizontal shear at notches and connections in members, a CH value of 1.5 is recommended for use with provisions in NDS•3.4.4 and 3.4.5 for dimensional lumber only.

Size Factor (CF)

Tabulated design values in the NDS-S are based on testing conducted on members of certain sizes. The specified depth for dimensional lumber members subjected to testing is 12 inches for No. 3 or better, 6 inches for stud-grade members, and 4 inches for construction-, standard- or utility-grade members (i.e., CF=1.0).

The size of a member affects unit strength because of the member’s relationship to the likelihood of naturally occurring defects in the material. Therefore, an adjustment to certain tabulated values is appropriate for sizes other than those tested; however, the tabulated values for southern yellow pine have already been adjusted for size and do not require application of CF. Table 5.2 indicates the tabulated values that should be adjusted to account for size differences. The adjustment applies when visually graded lumber is 2 to 4 inches thick or when a minimum 5-inch-thick rectangular bending member exceeds 12 inches in depth. Refer to NDS-S for the appropriate size adjustment factor.

Column Stability Factor (CP)

Tabulated compression design values in the NDS-S are based on the assumption that a compression member is continuously supported along its length to prevent lateral displacement in both the weak and strong axes. When a compression member is subject to continuous lateral support in at least two orthogonal directions, Euler buckling cannot occur. However, many compression members (e.g., interior columns or wall framing) do not have continuous lateral support in two directions.

The column stability factor, CP, adjusts the tabulated compression stresses to account for the possibility of column buckling. For rectangular or non-symmetric columns, CP must be determined for both the weak- and strong-axis bracing conditions. CP is based on end-fixity, effective length of the member between lateral braces, and the cross-sectional dimensions of the member that affect the slenderness ratio used in calculating the critical buckling stress. Given that the Euler buckling effect is associated only with axial loads, the CP factor applies to the allowable compressive stress parallel to grain, Fc, as shown in Table 5.2.

Beam Stability Factor (CL)

The tabulated bending design values, Fb, given in the NDS-S are applicable to bending members that are either braced against lateral-torsional buckling (i.e., twisting) or stable without bracing (i.e., the depth is no greater than the breadth of the member). Most bending members in residential construction are laterally supported on the compression edge by some type of sheathing product. The beam stability factor does, however, apply to conditions such as ceiling joists supporting unfinished attic space. When a member does not meet the lateral support requirements of NDS 3.3.3 or the stability requirements of NDS 4.4.1, the inspector should modify the tabulated bending design values by using the beam stability factor, CL, to account for the possibility of lateral-torsional buckling. For glued laminated timber bending members, the volume factor (CV) and beam stability factor (CL) are not applied simultaneously; thus, the lesser of these factors applies. Refer to the NDS 3.3.3 for the equations used to calculate CL.

Structural Evaluation

As with any structural design, the inspector should perform several checks with respect to various design factors. This section provides an overview of checks specified in the NDS and specifies several design concerns that are not addressed by the NDS. In general, the two categories of structural design concerns are:

• Structural Safety (strength)

• Structural Safety (strength)

◦ Bending and lateral stability

◦ Horizontal shear

◦ Bearing

◦ Combined bending and axial loading

◦ Compression and column stability

◦ Tension

• Structural Serviceability

◦ Deflection due to bending

◦ Floor vibration

◦ Shrinkage

Structural Safety Checks

Bending (Flexural) Capacity

The following equations from the NDS determine if a member has sufficient bending strength. Notches in bending members should be avoided, but small notches are permissible; refer to NDS 3.2.3. Similarly, the diameter of holes in bending members should not exceed one-third the member’s depth and should be located along the centerline of the member. Greater flexural capacity may be obtained by increasing member depth, decreasing the clear span or spacing of the member, or selecting a grade and species of lumber with a higher allowable bending stress. Engineered wood products or alternative materials may also be considered.

Horizontal Shear

Because shear parallel to grain (i.e., horizontal shear) is induced by bending action, it is also known as bending shear and is greatest at the neutral axis. Bending shear is not transverse shear; lumber will always fail in other modes before failing in transverse or cross-grain shear owing to the longitudinal orientation of the wood fibers in structural members.

The horizontal shear force is calculated for solid-sawn lumber by including the component of all loads (uniform and concentrated) that act perpendicular to the bearing surface of the solid member in accordance with NDS 3.4.3. Loads within a distance, d, from the bearing point are not included in the horizontal shear calculation; d is the depth of the member for solid rectangular members. Transverse shear is not a required design check, although it is used to determine the magnitude of horizontal shear by using basic concepts of engineering mechanics as discussed below.

The following equations from NDS 3.4 for horizontal shear analysis are limited to solid flexural members, such as solid-sawn lumber, Glulam®, or mechanically laminated beams. Notches in beams can reduce shear capacity and should be considered in accordance with NDS 3.4.4. Also, bolted connections influence the shear capacity of a beam; refer to NDS 3.4.5. If required, greater horizontal shear capacity may be obtained by increasing member depth or width, decreasing the clear span or spacing of the member, or selecting another species with a higher allowable shear capacity. The general equation for horizontal shear stress is discussed in the NDS and in mechanics of materials textbooks. Because dimensional lumber is solid and rectangular, the simple equation for fv is most commonly used.

Compression Perpendicular to Grain (Bearing)

For bending members bearing on wood or metal, a minimum bearing of 1.5 inches is typically recommended. For bending members bearing on masonry, a minimum bearing of 3 inches is typically advised. The resulting bearing areas may not, however, be adequate in the case of heavily loaded members. On the other hand, they may be too conservative in the case of lightly loaded members. The minimum bearing lengths are considered to represent good practice.

The following equations from the NDS are based on net bearing area. Note that the provisions of the NDS acknowledge that the inner bearing edge experiences added pressure as the member bends. As a practical matter, the added pressure does not pose a problem because the compressive capacity, Fc⊥, of wood increases as the material is compressed. Further, the design value is based on a deformation limit, not on failure by crushing. Thus, the NDS recommends the added pressure at bearing edges not be considered. The inspector is also alerted to the use of the bearing area factor, Cb, which accounts for the ability of wood to distribute large stresses originating from a small bearing area not located near the end of a member. Examples include interior bearing supports and compressive loads on washers in bolted connections.

The above equations pertain to bearing that is perpendicular to grain; for bearing at an angle to grain, refer to NDS 3.10. The later condition would apply to sloped bending members (i.e., rafters) notched at an angle for bearing. For light-frame construction, bearing stress is rarely a limiting factor.

Combined Bending and Axial Loading

Depending on the application and the combination of loads considered, some members, such as wall studs and roof truss members, experience bending stress in addition to axial loading. The inspector should evaluate combined bending and axial stresses as appropriate. If additional capacity is required, the selection of a higher grade of lumber is not always an efficient solution for over-stressed compression members under combined axial and bending loads because the design may be limited by stability rather than by a stress failure mode. Efficiency issues will become evident when the inspector calculates the components of the combined stress interaction equations that are given below and found in the NDS.

Compression and Column Stability

For framing members that support axial loads only (i.e., columns), the inspector must consider whether the framing member can withstand the axial compressive forces on it without buckling or compressive failure. If additional compression strength is required, the inspector should increase member size, decrease framing member spacing, provide additional lateral support, or select a different grade and species of lumber with higher allowable stresses. Improving lateral support is usually the most efficient solution when stability controls the design (disregarding any architectural limitations). The need for improved lateral support will become evident when the inspector performs the calculations necessary to determine the stability factor, CP, in accordance with NDS 3.7. When a column has continuous lateral support in two directions, buckling is not an issue and CP = 1.0. If, however, the column is free to buckle in one or more directions, CP must be evaluated for each direction of possible buckling. The evaluation must also consider the spacing of intermediate bracing, if any, in each direction.

Tension

Relatively few members in light-frame construction resist tension forces only. One notable exception occurs in roof framing where cross-ties or bottom chords in trusses primarily resist tension forces. Other examples include chord and collector members in shear walls and horizontal diaphragms. Another possibility is a member subject to excessive uplift loads, such as those produced by extreme wind. In any event, connection design is usually the limiting factor in designing the transfer of tension forces in light-frame construction. Tension stresses in wood members are checked by using the equations below in accordance with NDS 3.8.

The NDS does not provide explicit methods for evaluating cross-grain tension forces and generally recommends the avoidance of cross-grain tension in lumber even though the material is capable of resisting limited cross-grain stresses. Design values for cross-grain tension may be approximated by using one-third of the unadjusted horizontal shear stress value Fv. One application of cross-grain tension in design is in the transfer of moderate uplift loads from wind through the band or rim joist of a floor to the construction below. If additional cross-grain tension strength is required, the inspector should increase member size or consider alternative construction details that reduce cross-grain tension forces. When excessive tension stress perpendicular to grain cannot be avoided, the use of mechanical reinforcement or design detailing to reduce the cross-grain tension forces is considered good practice (particularly in high-hazard seismic regions) to ensure that brittle failures do not occur.

Structural Serviceability

Deflection Due to Bending

The NDS does not specifically limit deflection but rather defers to inspector judgment or building code specifications. Nonetheless, with many interior and exterior finishes susceptible to damage by large deflections, reasonable deflection limits based on design loads are recommended herein for the design of specific elements.

The calculation of member deflection is based on the section properties of the beam from NDS-S and the member’s modulus of elasticity with applicable adjustments. Generally, a deflection check using the equations below is based on the estimated maximum deflection under a specified loading condition. Given that wood exhibits time- and load-magnitude-dependent permanent deflection (creep), the total long-term deflection can be estimated in terms of two components of the load related to short- and long-term deflection using recommendations provided in NDS 3.5.

If a deflection check proves unacceptable, the inspector may increase member depth, decrease the clear span or spacing of the member, or select a grade and species of wood with a higher modulus of elasticity (the least effective option). Typical denominator values used in the deflection equation range from 120 to 600, depending on application and inspector judgment. Table 5.5 provides recommended deflection limits. Certainly, if a modest adjustment to a deflection limit results in a more efficient design, the inspector should exercise discretion with respect to a possible negative consequence, such as vibration or long-term creep. For lateral bending loads on walls, a serviceability load for a deflection check may be considered as a fraction of the nominal design wind load for exterior walls. A reasonable serviceability wind load criteria may be taken as 0.75W or 75% of the nominal design wind load.

TABLE 5.5 Recommended Allowable Deflection Limits

Given that system effects influence the stiffness of assemblies in a manner similar to that of bending capacity (see Section 5.2.4.2), the system deflection factors of Table 5.6 are recommended. The estimated deflection based on an analysis of an element (e.g., stud or joist) is multiplied by the deflection factors to account for system effect. Typical deflection checks on floors under uniform loading can be easily overestimated by 20% or more. In areas where partitions add to the rigidity of the supporting floor, deflection can be overestimated by more than 50% (Hurst, 1965). When concentrated loads are considered on typical light-frame floors with wood structural panel subflooring, deflections can be overestimated by a factor of 2.5 to 3 due to the neglect of the load distribution to adjacent framing members and partial composite action (Tucker and Fridley, 1999). Similar results have been found for sheathed wall assemblies (NAHBRF, 1974). When adhesives attach wood structural panels to wood framing, even greater reductions in deflection are realized due to increased composite action (Gillespie et al., 1978; Pellicane and Anthony, 1996). However, if a simple deflection limit, such as /360, is construed to control floor vibration in addition to the serviceability of finishes, the use of system deflection factors of Table 5.6 is not recommended for floor system design. In this case, a more accurate estimate of actual deflection may result in a floor with increased tendency to vibrate or bounce.

TABLE 5.6 System Deflection Adjustment Factors

Floor Vibration

The NDS does not specifically address floor vibration because it is a serviceability rather than a safety issue. In addition, what is considered an acceptable amount of floor vibration is highly subjective. Accordingly, reliable design information on controlling floor vibration to meet a specific level of acceptance is not readily available; therefore, some rules of thumb are provided below for the inspector wishing to limit vibration beyond that implied by the traditional use of an /360 deflection limit (FHA, 1958; Woeste and Dolan, 1998).

- For floor joist spans less than 15 feet, a deflection limit of /360 considering design live loads only may be used, where is the clear span of the joist in inches.

- For floor joist clear spans greater than 15 feet, the maximum deflection should be limited to 0.5 inches.

- For wood I-joists, the manufacturer’s tables that limit deflection to /480 should be used for spans greater than 15 feet, where is the clear span of the member in inches.

- When calculating deflection based on the above rules of thumb, the inspector should use a 40 psf live load for all rooms, whether or not they are considered sleeping rooms.

- As an additional recommendation, glue and mechanically fasten the floor sheathing to the floor joists to enhance the floor system’s strength and stiffness.

Floor deflections are typically limited to /360 in the span tables published in current building codes using a standard deflection check without consideration of system effects. For clear spans greater than 15 feet, this deflection limit has caused nuisance vibrations that are unacceptable to some building occupants or owners. Floor vibration is also aggravated when the floor is supported on a bending member (e.g., girder) rather than on a rigid bearing wall. It may be desirable to design such girders with a smaller deflection limit to control floor vibration, particularly when girder and floor spans have more than a 20-foot total combined span (i.e., span of girder plus span of supported floor joist).

For metal plate-connected wood trusses, strong-backs are effective in reducing floor vibration when they are installed through the trusses near the center of the span. A strong-back is a continuous bracing member, typically a 2x6, fastened edgewise to the base of the vertical web of each truss with two 16d nails. For longer spans, strong-backs may be spaced at approximately 8-foot intervals across the span. Details for strong-backs may be found in the Metal Plate-Connected Wood Truss Handbook (WTCA, 1997). Alternatively, a more stringent deflection criteria may be used for the floor truss design.

Shrinkage

The amount of wood shrinkage in a structure depends on the moisture content (MC) of the lumber at the time of installation relative to the equilibrium moisture content (EMC) that the wood will ultimately attain in use. It is also dependent on the detailing of the structure, such as the amount of lumber supporting loads in a perpendicular-to-grain orientation (i.e., sill, sole, top plates and joists). MC at installation is a function of the specified drying method, jobsite storage practices, and climate conditions during construction. Relatively dry lumber (15% or less) minimizes shrinkage problems affecting finish materials and prevents loosening or stressing of connections. A less favorable but acceptable alternative is to detail the structure such that shrinkage is uniform, dispersed, or otherwise designed to minimize problems. This alternative is the defacto choice in simple residential buildings.

Shrinking and swelling across the width or thickness of lumber can be estimated by the equation below from ASTM D1990 for typical softwood structural lumber (ASTM, 1998a). Shrinkage in the longitudinal direction of the member is practically negligible.

Floor Framing

The objectives of floor system design are:

- to support occupancy live loads and building dead loads adequately;

- to resist lateral forces resulting from wind and seismic loads and to transmit the forces to supporting shear walls through diaphragm action;

- to provide a suitable subsurface for floor finishes;

- to avoid owner complaints (e.g., excessive vibration, noise, etc.);

- to serve as a thermal barrier over unconditioned areas (e.g., crawl spaces); and

- to provide a one- to two-hour fire rating between dwelling units in multi-family buildings (refer to local building codes).

General

A wood floor is a horizontal structural system composed primarily of the following members:

◦ joists;

◦ girders; and

◦ sheathing.

Wood floor systems have traditionally been built of solid-sawn lumber for floor joists and girders, although parallel chord wood trusses and wood I-joists are seeing increasing use, and offer advantages for dimensional consistency, and spans. Floor joists are horizontal, repetitive framing members that support the floor sheathing and transfer the live and dead floor loads to the walls, girders, or columns below. Girders are horizontal members that support floor joists not otherwise supported by interior or exterior load-bearing walls. Floor sheathing is a horizontal structural element, usually plywood or oriented strand board panels, that directly supports floor loads and distributes the loads to the framing system below. Floor sheathing also provides lateral support to the floor joists. As a structural system, the floor provides resistance to lateral building loads resulting from wind and seismic forces and thus constitutes a horizontal diaphragm. Refer to Figure 5.2 for an illustration of floor system structural elements and to Cost-Effective Home Building: A Design and Construction Handbook for efficient design ideas and concepts.

FIGURE 5.2 Structural Elements of the Floor System

The design approach discussed herein addresses solid-sawn lumber floor systems in accordance with the procedures specified in the National Design Specification for Wood Construction (NDS), with appropriate modifications as noted. For more information regarding wood I-joists, trusses, and other materials, consult the manufacturer’s specifications and applicable code evaluation reports.

When inspecting any structural element, the inspector must first determine the loads acting on the element. Given that only the dead loads of the floor system and live loads of occupancy are present in a typical floor system, the controlling design load combination for a simply-supported floor joist is D+L.

For joists with more complicated loading, such as cantilevered joists supporting roof framing, the following load combinations may be considered:

Readily available tables in residential building codes provide maximum allowable spans for different species, grades, sizes, and spacings of lumber joists. Some efficient concepts for floor joist design are also provided in Cost-Effective Home Building: A Design and Construction Handbook (NAHB). Therefore, it is usually not necessary to design conventional floor joists for residential construction. To obtain greater economy or performance, however, inspectors may wish to create their own span tables or spreadsheets for future use in accordance with the methods shown in this section.

Keep in mind that the grade and species of lumber is often a regional choice governed by economics and availability; some of the most common species of lumber for floor joists are hem-fir, spruce-pine-fir, Douglas fir, and southern yellow pine. Bear in mind, too, that the most common sizes for floor joists are 2x8 and 2x10, although 2x12s are also frequently used.

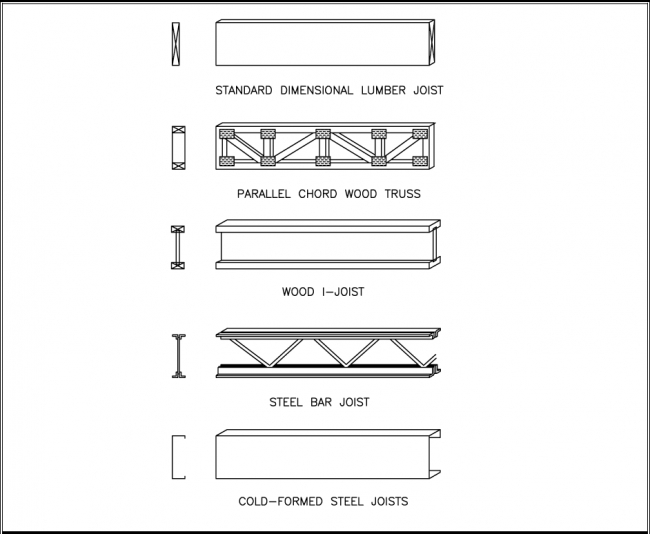

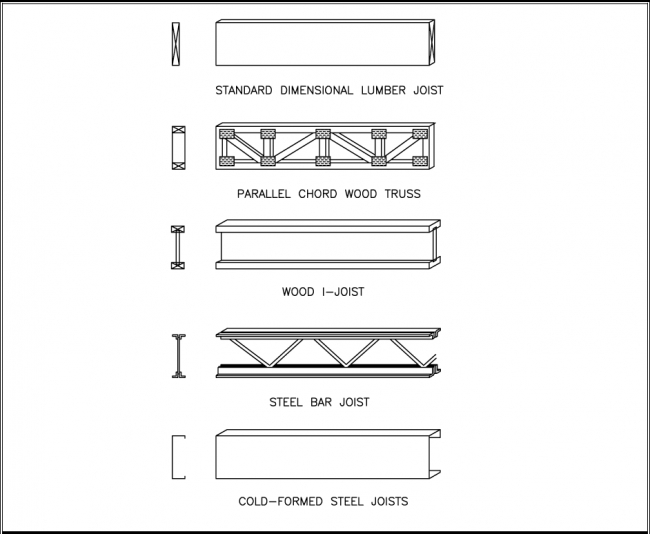

For different joist applications, such as a continuous multiple span, the inspector should use the appropriate beam equations to estimate the stresses induced by the loads and reactions. Other materials, such as wood I-joists and parallel chord floor trusses, are also commonly used in light-frame residential and commercial construction; refer to the manufacturer’s data for span tables for wood I-joists and other engineered wood products. Cold-formed steel floor joists or trusses may also be considered. Figure 5.3 illustrates some conventional and alternative floor joist members.

D + LFloor Joist Design

D + L + 0.3 (Lr or S)

D + (Lr or S) + 0.3L

Readily available tables in residential building codes provide maximum allowable spans for different species, grades, sizes, and spacings of lumber joists. Some efficient concepts for floor joist design are also provided in Cost-Effective Home Building: A Design and Construction Handbook (NAHB). Therefore, it is usually not necessary to design conventional floor joists for residential construction. To obtain greater economy or performance, however, inspectors may wish to create their own span tables or spreadsheets for future use in accordance with the methods shown in this section.

Keep in mind that the grade and species of lumber is often a regional choice governed by economics and availability; some of the most common species of lumber for floor joists are hem-fir, spruce-pine-fir, Douglas fir, and southern yellow pine. Bear in mind, too, that the most common sizes for floor joists are 2x8 and 2x10, although 2x12s are also frequently used.

For different joist applications, such as a continuous multiple span, the inspector should use the appropriate beam equations to estimate the stresses induced by the loads and reactions. Other materials, such as wood I-joists and parallel chord floor trusses, are also commonly used in light-frame residential and commercial construction; refer to the manufacturer’s data for span tables for wood I-joists and other engineered wood products. Cold-formed steel floor joists or trusses may also be considered. Figure 5.3 illustrates some conventional and alternative floor joist members.

FIGURE 5.3 Conventional and Alternative Floor Framing Members

For typical floor systems supporting a concentrated load at or near center span, load distribution to adjacent joists can substantially reduce the bending stresses or moment experienced by the loaded joist. A currently available design methodology may be beneficial for certain applications, such as wood-framed garage floors that support heavy concentrated wheel loads. Under such conditions, the maximum bending moment experienced by any single joist is reduced by more than 60%. A similar reduction in the shear loading (and end reaction) of the loaded joist also results, with exceptions for moving concentrated loads that may be located near the end of the joist, thus creating a large transverse shear load with a small bending moment. The above-mentioned design methodology for a single, concentrated load applied near mid-span of a repetitive member floor system is essentially equivalent to using a Cr factor of 1.5 or more. The system deflection adjustment factors in Table 5.6 are applicable as indicated for concentrated loads.

Bridging or cross-braces were formerly thought to provide both necessary lateral-torsional bracing of dimensional lumber floor joists and stiffer floor systems. However, full-scale testing of 10 different floor systems as well as additional testing in completed homes has conclusively demonstrated that bridging or cross-bracing provides negligible benefit to either the load-carrying capacity or stiffness of typical residential floors with dimensional lumber framing (sizes of 2x6 through 2x12) and wood structural panel subflooring (NAHB, 1961). These same findings are not proven to apply to other types of floor joists (i.e., I-joists, steel joists, etc.) or for dimensional lumber joists greater than 12 inches in depth. According to the study, bridging may be considered necessary for 2x10 and 2x12 dimensional lumber joists with clear spans exceeding about 16 feet and 18 feet, respectively (based on a 50 psf total design load and L/360 deflection limit). To the contrary, the beam stability provisions of NDS 4.4.1 conservatively require bridging to be spaced at intervals not exceeding 8 feet along the span of 2x10 and 2x12 joists.

Girder Design

The decision to use one girder over another is a function of cost, availability, span and loading conditions, clearance or head-room requirements, and ease of construction. Refer to the Figure 5.4 for illustrations of girder types.

For typical floor systems supporting a concentrated load at or near center span, load distribution to adjacent joists can substantially reduce the bending stresses or moment experienced by the loaded joist. A currently available design methodology may be beneficial for certain applications, such as wood-framed garage floors that support heavy concentrated wheel loads. Under such conditions, the maximum bending moment experienced by any single joist is reduced by more than 60%. A similar reduction in the shear loading (and end reaction) of the loaded joist also results, with exceptions for moving concentrated loads that may be located near the end of the joist, thus creating a large transverse shear load with a small bending moment. The above-mentioned design methodology for a single, concentrated load applied near mid-span of a repetitive member floor system is essentially equivalent to using a Cr factor of 1.5 or more. The system deflection adjustment factors in Table 5.6 are applicable as indicated for concentrated loads.

Bridging or cross-braces were formerly thought to provide both necessary lateral-torsional bracing of dimensional lumber floor joists and stiffer floor systems. However, full-scale testing of 10 different floor systems as well as additional testing in completed homes has conclusively demonstrated that bridging or cross-bracing provides negligible benefit to either the load-carrying capacity or stiffness of typical residential floors with dimensional lumber framing (sizes of 2x6 through 2x12) and wood structural panel subflooring (NAHB, 1961). These same findings are not proven to apply to other types of floor joists (i.e., I-joists, steel joists, etc.) or for dimensional lumber joists greater than 12 inches in depth. According to the study, bridging may be considered necessary for 2x10 and 2x12 dimensional lumber joists with clear spans exceeding about 16 feet and 18 feet, respectively (based on a 50 psf total design load and L/360 deflection limit). To the contrary, the beam stability provisions of NDS 4.4.1 conservatively require bridging to be spaced at intervals not exceeding 8 feet along the span of 2x10 and 2x12 joists.

Girder Design

The decision to use one girder over another is a function of cost, availability, span and loading conditions, clearance or head-room requirements, and ease of construction. Refer to the Figure 5.4 for illustrations of girder types.