Advanced HVAC Training for Home Inspectors Course

Welcome to InterNACHI's free, online "Advanced HVAC Training for Home Inspectors Course." This course is provided by our accredited college at internachi.edu.

Welcome to InterNACHI's free, online "Advanced HVAC Training for Home Inspectors Course." This course is provided by our accredited college at internachi.edu. Goal:

The goal of this training video is to teach home inspectors how to perform visual inspections of HVAC systems in homes.

Objective:

Upon successful completion of this course, the student shall be able to:

- inspect heating and cooling systems;

- evaluate the basic performance of HVAC systems;

- describe how HVAC systems and related components function and perform; and

- identify and report major defects common to HVAC systems.

Course includes:

- 39.0 InterNACHI® CE credit hours;

- 8,894 words in the course textbook;

- 16.5 hours of instructional video;

- technical illustration and inspection images;

- inspection and writing assignment;

- research and writing assignment;

- 16 quiz questions for review reinforcement;

- a 150-question final exam (drawn from a larger pool);

- instant grading; and

- a downloadable, printable Certificate of Completion.

You will learn the following topics:

- furnaces: gas, oil, electric, solid fuel, air distribution systems, filtration devices, classification, efficiency, components, cabinet, valves, burner assembly, blower and motor, controls and electronics, pilot light assembly, safety controls, igniter, flame sensor, flame and limit controls, operation sequence, draft hood, combustion blower, inducer fan, heat exchanger: cast iron, heavy gauge welded, clamshell, serpentine, tubular, secondary condensing,

boilers: classification, water, steam, fuel type, material of construction, dry base, wet base, water tube, fire tube, type of draft, condensing, wall hung, integrated domestic coil, components, gas valve, safety controls, burner assembly, heat exchanger, temperature pressure relief valve, auto fill valve, sight glass, low water cut off, expansion tank, zone valves, circulator pump, air separator, temperature gauge, high low limit control, backflow preventer, oil burner, pump, blower, nozzle, ignitor, transformer, electric motor, air shutter, reset switches, cad cell, stack switch, radiators, convectors, finned tube, fan coil

boilers: classification, water, steam, fuel type, material of construction, dry base, wet base, water tube, fire tube, type of draft, condensing, wall hung, integrated domestic coil, components, gas valve, safety controls, burner assembly, heat exchanger, temperature pressure relief valve, auto fill valve, sight glass, low water cut off, expansion tank, zone valves, circulator pump, air separator, temperature gauge, high low limit control, backflow preventer, oil burner, pump, blower, nozzle, ignitor, transformer, electric motor, air shutter, reset switches, cad cell, stack switch, radiators, convectors, finned tube, fan coil - piping systems: gas piping systems, rigid pipe (steel), black iron, painted outdoors, pipe dope, no Teflon tape, drip leg, gas cock, union, flex connectors, ANSI listed corrugated stainless, protected from damage, no wall penetration, no copper tubing, hydronic, type M or L, galvanized iron, refrigerant

- heat pump systems: reverse cycle air-conditioning system, efficiency, defrost cycle, back-up electric heat, thermostat, controls, standard open contact switch, magnetic strip, mercury switch, set back, thermostat, thermostatic expansion valves, variable speed blowers, coil design, electric motor, compressor, copper tubing, efficiency

- chimneys and venting systems: masonry chimneys, fabricated steel stack, factory vent pipe, type B gas vent, category I, type BW gas vent, type L, plastic for condensing furnaces, category IV, direct vent systems, vent installations, type B vent, category I appliances, sizing, multiple appliances, IFGC, old method, non-fan assisted combustion, minimum slope, minimum stack height, termination, exceptions, clearance to combustibles, liners and interior flues, cleanout, vent connector, length and height, B vent, un-vented appliances, room heaters, free-standing fireplaces, burner capacity

- in space systems: room heaters, wall furnaces, floor furnaces, fireplaces, pellet stoves and furnaces, fireplaces, pellet stoves, and furnaces, radiant and/or convective heat, conventional or direct vent, surface or recessed wall mount, blower, oil and kerosene heaters, infra-red

humidification devices: in duct, pan, spray nozzle, spinning disc, wetted drum, disc, brush, power, bypass, wetted element, portable appliance types, commercial, ultrasonic, electrode steam, self-contained

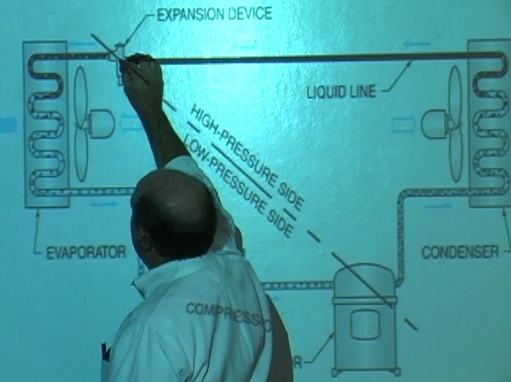

humidification devices: in duct, pan, spray nozzle, spinning disc, wetted drum, disc, brush, power, bypass, wetted element, portable appliance types, commercial, ultrasonic, electrode steam, self-contained- central air cooling systems: refrigeration cycle, major components, compressor, condenser and fan, metering device, evaporator, sequence of operation, thermostat, pressure equalization, compressor condenser, blower, condensate pump, system shut down, compressor, hermetic, semi-hermetic, condenser and fan, metering devices, expansion valve, piston, capillary tube, evaporator, cooling coil, refrigeration cycle, contactor, capacitor, high-pressure switch, low-temperature switch, crankcase heater, thermal overload, crankcase heater, thermal overload, filter drier, package units

- evaporative coolers: down-flow, ground-mounted horizontal, windows, portable, controls, components, filters, pads, reservoir, two-stage, pre-cooler, efficient motors, water pump, blower

- defects: rust and corrosion, ignition failure, pilot failures, thermocouples, flame sensors, combustion blowers, pressure switches, air mixture, limit and spill switches, vent defects, too small, too big, corrosion, improper pitch, vent termination, connector clearance, flue clearance, liner failure, cleanouts, spillage, barometric dampers, corrosion, blower issues, requirements, prohibited locations, exceptions, clearances, access, leakage, relief valve leakage, waterlogged expansion tank, high pressure, pump noise, low water cutoff, leaky sill cock, blowdown valve, zone valve failure, combustion air, confined spaces, poor locations, improper sizing, ventilation problems, damper faults, spillage, heat exchanger failures, carbon monoxide, poor combustion, air mixture, delay ignition, fuel-air mix, duct air unbalanced, duct sizing improper, defects at registers, temperature rise, vibration, belts, sheaves, dust and debris, low efficiency, poor selection, oversized, poor installation workmanship, asbestos, filter problems

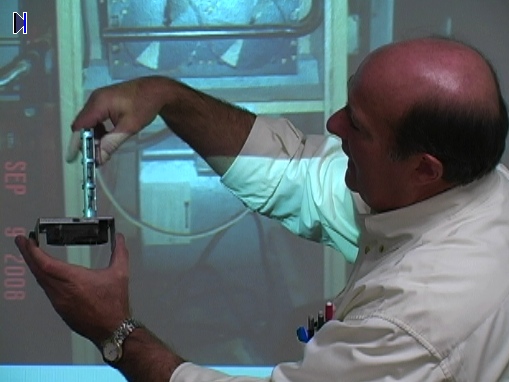

- inspection tools: must-haves, flashlight, inspection mirror, thermometer, screwdrivers, voltage detector alarm pen, #2 straight, #2 Phillips, nut drivers, 1/4”, 5/16”, CO detector, hygrometer, psychrometer, micro-manometer, Magnehelic, infra-red thermometer, insertion thermometer, boroscope, cordless drill, cap plugs

| Advanced HVAC Training for Home Inspectors Course | ||

|---|---|---|

| Course #3802, Student Catalog | ||

| www.nachi.org/advanced-training-inspecting-hvac-systems-online-video-course | ||

| Student Work | Time Calculation | Estimated Clock Hour Time for the Average Student |

| Attendance for "Seat Time" 1 | # of minutes of student attendance / 50 | 24.3 |

| Participation in Learning Activities 2 | # of minutes of online student participation / 50 | 1.0 |

| Interactivity 3 | # of minutes of student interactivity / 50 | 0.5 |

| Reading the Course Text 4 | # of words in the course / 100 words per minute / 50 | 0.5 |

| Reading the Course Textbook 5 | # of words in the book / 100 words per minute / 50 | 1.0 |

| Academic Engagement 6 | # of words in the course / 100 / 50 | 0.5 |

| Direct Communication 7 | # of minutes of communication / 50 | 0.5 |

| Instructional Video Learning 8 | # of minutes of video / 50 | 19.8 |

| Reinforcement Q & A 9 | # of questions X 1.85 / 50 | 0.5 |

| Writing Assignment of the Inspection 10 | 2.0 hours per assignment | 2.0 |

| Writing Assignment of the Research 11 | 3.0 hours per assignment | 3.0 |

| Academic Activities for an Inspection 12 | 4.0 hours for each inspection assignment | 4.0 |

| Performing an Inspection 13 | 6.0 hours for each inspection | 6.0 |

| * nachi.org/catalog-credit-hour-calculation | 39.3 | |

| Total clock hours | 39.0 clock hours 39.0 InterNACHI CE Hours 3.9 CEU | |

And, in keeping with InterNACHI's commitment to Continuing Education, this online training course is open and free to all Nevada members, and can be taken again and again, without limit.

And, in keeping with InterNACHI's commitment to Continuing Education, this online training course is open and free to all Nevada members, and can be taken again and again, without limit.

Reminder to members: InterNACHI's Code of Ethics 1.10 requires that you comply with all government rules and licensing requirements of the jurisdiction where you conduct business. InterNACHI's courses and Standards generally exceed the Standards of Practice that you are required to abide by locally.

This course has been approved by:

- the International Association of Certified Home Inspectors;

- the Master Inspector Certification Board;

- the International Association of Certified Indoor Air Consultants;

- the Certified Commercial Property Inspectors Association; and

- many government agencies and licensing boards.

Upon completion of this course and passing of the 150-question final exam (drawn from a larger pool), the student can download and print his/her own Certificate of Completion, which is auto-generated in the student's own name.

The student's (InterNACHI member's) information is recorded on InterNACHI's servers for membership compliance verification, and automatically logs completion into InterNACHI's online Continuing Education log.

Non-members may view only the first page of the course.

Members will need their username and password. If you have forgotten your password, CLICK HERE (instant response) or email fastreply@internachi.org and request it (don't forget your name).

Some features which make InterNACHI's courses superior to existing continuing education options:

- The course is free for all InterNACHI members.

- The course is written in pure XHTML code for quick loading. The course loads fine on old computers and loads fast, even with dial-up.

- The course is designed using a hierarchal menu coupled with a sequential page navigation. This provides the student with the option to easily repeat areas of weakness.

- The course permits the student to start, stop and restart any part of the course as often as desired.

- There are a variety of images within the course, including diagrams, illustrations and photos.

- The illustrations can be enlarged for clearer viewing by clicking on them.

- The text is integrated into InterNACHI's Inspector Glossary. Rolling over blue-colored terms provides their definition.

- The final exam uses multiple-choice questions that reference the images.

- The course's quizzes and final exam have numerous advantages over traditional exam systems:

- The course, quizzes and final exam incorporate built-in intelligence which identifies and strengthens each student's unique subject weaknesses.

- Not only is each question weighted with regard to score, but each answer is weighted, as well as the correctness of each answer being weighted.

- Answers to easy questions are weighted such that the student is penalized, in terms of score, for answering incorrectly, but rewarded modestly for answering correctly.

- Answers to difficult questions are weighted such that the student is rewarded, in terms of score, for answering correctly, but not penalized for answering incorrectly.

- Answers to questions regarding basic safety, or questions every inspector should know the answer to, are weighted such that the student is severely penalized, in terms of score, for answering incorrectly.

- Upon passing the final exam, the student can print out a Certificate of Completion which is auto-generated in their own name.

The student's (InterNACHI member's) information is recorded on InterNACHI's servers for membership compliance verification, and automatically logs completion into InterNACHI's online Continuing Education log.